We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Ingress Protection: What your Electrical Enclosure's IP Rating Means

What does the IP in IP Rating stand for?

IP stands for Ingress Protection. "Ingress" means "getting in", so Ingress Protection means "keeping things out". Therefore, the IP rating of an electrical enclosure is a standardised code that shows how resistant that enclosure is to solids (usually dust and dirt) and liquids (usually water). The IP rating is defined by the IEC international standard IEC 60529, adopted in the UK and EU, and used globally across industry.

IP Rating Code Breakdown

An IP code always starts with the letters IP, followed by two digits and sometimes extra letters. Like this:

IP [Digit A)] [Digit B] [optional letters]

- A = protection against solids (first digit: 0–6 or X)

- B = protection against water (second digit: 0–9 or X)

- Optional letters add extra detail (explained further below)

If a digit is replaced by X, it means that part of the test was not carried out or is not specified. For example:

- IPX4: No test for solids, but splashing water protection confirmed.

- IP5X: Dust protected, no test for water.

There are no hyphens in an official IP rating. “IPX-8” is incorrect - the correct format is “IPX8”.

First Digit: Protection Against Solids (0–6)

This digit shows how much protection the enclosure gives against people touching live parts and against dust or solid objects entering.

| Digit | Protection level | Example code |

|---|---|---|

| 0 | No protection | IP00 – no solids or water protection |

| 1 | Back of hand; objects ≥ 50 mm | IP10 – stops accidental hand contact, but not much else |

| 2 | Finger; objects ≥ 12.5 mm | IP20 – prevents fingers reaching live parts, common for indoor switchgear |

| 3 | Tool; objects ≥ 2.5 mm | IP30 – stops entry of most tools or thick wires |

| 4 | Wire; objects ≥ 1.0 mm | IP44 – stops thin wires or screws entering; also resists splashes |

| 5 | Dust protected (limited ingress, no harmful deposit) | IP55 – protected from harmful dust and water jets |

| 6 | Dust-tight (no ingress at all) | IP66 – fully dust-tight and resistant to powerful water jets |

Second Digit: Protection Against Water (0–9)

This digit shows how waterproof your enclosure is.

| Digit | Protection level | Example code |

|---|---|---|

| 0 | No protection | IP60 – dust-tight, but no water protection |

| 1 | Dripping water (vertical) | IP21 – protects against condensation or light drips |

| 2 | Dripping water at 15° tilt | IP22 – often used for indoor lighting |

| 3 | Spraying water | IP23 – resists sprays at an angle |

| 4 | Splashing water | IP44 – common for outdoor sockets and garden lights |

| 5 | Water jets | IP65 – safe against hose-down cleaning |

| 6 | Powerful water jets | IP66 – used in washdown areas |

| 7 | Temporary immersion (up to 1 m for 30 min, per test spec) | IP67 – used outdoors or in pits subject to flooding |

| 8 | Continuous immersion (conditions agreed with supplier) | IP68 – underwater sensors, submersible pumps |

| 9 | High-pressure, hot water jets (IEC 60529:2013) | IP69 – food-processing and hygienic equipment |

Optional Letters in IP Codes

In addition to the two digits, some IP ratings include letters to give more detail about the type of protection or the way testing was carried out. These letters are not always present, but when they are, they help specify exactly how the enclosure has been tested.

Breakdown of Each Letter

| Letter | Meaning | Explanation | Example |

|---|---|---|---|

| A | Back of hand protection | Tested with a probe shaped like the back of a hand. Ensures large accidental contact cannot reach live parts. | IP2XA – prevents accidental hand contact. |

| B | Finger protection | Tested with a standard finger probe (12.5 mm diameter). Ensures fingers cannot touch hazardous parts. | IP2XB – finger-safe plus water protection. |

| C | Tool protection | Tested with a probe representing a small tool (2.5 mm diameter). Ensures tools cannot reach live parts. | IP3XC – tool-safe, useful for maintenance areas. |

| D | Wire protection | Tested with a probe like a fine wire (1.0 mm). Ensures even small wires cannot enter. | IP4XD – wire-safe and splash resistant. |

| H | High-voltage equipment | Indicates the enclosure is designed for and tested with high-voltage apparatus. | IP2XH – for high-voltage switchgear. |

| M | Moving during test | The equipment was operating/moving while water testing was performed. | IPX5M – water jet test carried out while motors were running. |

| S | Stationary during test | The equipment was not operating during water testing. | IPX5S – tested at rest with water jets. |

| W | Weather conditions | Special weather-resistant testing. Often means extra gaskets or UV resistance. | IP66W – enclosure safe for outdoor use in harsh weather. |

So if you see something like IP2XC, it means:

- 2: Protection against fingers (≥ 12.5 mm)

- X: No test for water specified

- C: Tested with a tool probe as well, ensuring tool-proof protection

Or, IP66W means:

- 6: Dust-tight

- 6: Protected against powerful water jets

- W: Tested for weather resistance, making it suitable for outdoor use

Complete List of IP Ratings and Applications:

| IP Code | Solids Protection | Water Protection | Typical Use / Example |

|---|---|---|---|

| IP00 | No protection | No protection | Open equipment with no enclosure |

| IP01 | No protection | Dripping water (vertical) | Very rare; old indoor fixtures |

| IP02 | No protection | Dripping water at 15° tilt | Simple light fittings in sheltered areas |

| IP03 | No protection | Spraying water | Equipment in partially sheltered outdoor use |

| IP04 | No protection | Splashing water | Enclosures in protected outdoor settings |

| IP05 | No protection | Water jets | Basic housings exposed to hose-down |

| IP06 | No protection | Powerful water jets | Rare, as solids protection is usually required |

| IP07 | No protection | Temporary immersion | Experimental gear, not common |

| IP08 | No protection | Continuous immersion | Specialist housings, but usually dust protection is also added |

| IP09 | No protection | High-pressure hot water jets | Theoretically possible, but not seen in practice |

| IP10 | Objects ≥50 mm (hand) | No protection | Very basic indoor covers |

| IP11 | ≥50 mm | Drips (vertical) | Simple ceiling lights |

| IP12 | ≥50 mm | Drips at 15° | Sheltered lighting |

| IP13 | ≥50 mm | Sprays | Low-cost outdoor housings |

| IP14 | ≥50 mm | Splashes | Basic outdoor sockets |

| IP15 | ≥50 mm | Jets | Rare, minimal solids protection |

| IP16 | ≥50 mm | Powerful jets | Rare |

| IP17 | ≥50 mm | Temporary immersion | Specialist panels |

| IP18 | ≥50 mm | Continuous immersion | Rare |

| IP19 | ≥50 mm | Hot jets | Uncommon |

| IP20 | Fingers (≥12.5 mm) | No protection | Indoor panels, distribution boards |

| IP21 | Fingers | Drips (vertical) | Office lighting |

| IP22 | Fingers | Drips at 15° | Common in household appliances |

| IP23 | Fingers | Sprays | Some outdoor lighting fittings |

| IP24 | Fingers | Splashes | Weatherproof sockets (basic level) |

| IP25 | Fingers | Jets | Sheltered outdoor housings |

| IP26 | Fingers | Powerful jets | Rare |

| IP27 | Fingers | Temporary immersion | Garden electronics |

| IP28 | Fingers | Continuous immersion | Specialist immersion housings |

| IP29 | Fingers | Hot jets | Rare |

| IP30 | Tools (≥2.5 mm) | No protection | IT enclosures in clean areas |

| IP31 | Tools | Drips (vertical) | Lighting housings |

| IP32 | Tools | Drips at 15° | Indoor appliances |

| IP33 | Tools | Sprays | Some industrial lights |

| IP34 | Tools | Splashes | Outdoor distribution boards |

| IP35 | Tools | Jets | Machinery housings |

| IP36 | Tools | Powerful jets | Rare |

| IP37 | Tools | Temporary immersion | Specialist panels |

| IP38 | Tools | Continuous immersion | Rare |

| IP39 | Tools | Hot jets | Rare |

| IP40 | Wires (≥1.0 mm) | No protection | Computer cases, office electronics |

| IP41 | Wires | Drips (vertical) | Sheltered indoor equipment |

| IP42 | Wires | Drips at 15° | Small appliances |

| IP43 | Wires | Sprays | Indoor machinery |

| IP44 | Wires | Splashes | Outdoor sockets, bathroom lights |

| IP45 | Wires | Jets | Outdoor junction boxes |

| IP46 | Wires | Powerful jets | Harsh outdoor housings |

| IP47 | Wires | Temporary immersion | Garden control boxes |

| IP48 | Wires | Continuous immersion | Submersible pumps (limited) |

| IP49 | Wires | Hot jets | Specialist enclosures |

| IP50 | Dust protected | No water protection | Electronics in dusty factories |

| IP51 | Dust protected | Drips (vertical) | Workshop lights |

| IP52 | Dust protected | Drips at 15° | Industrial control boxes |

| IP53 | Dust protected | Sprays | Outdoor lighting |

| IP54 | Dust protected | Splashes | General indoor/outdoor enclosures |

| IP55 | Dust protected | Jets | Machine housings |

| IP56 | Dust protected | Powerful jets | Marine/harsh environments |

| IP57 | Dust protected | Temporary immersion | Outdoor control panels |

| IP58 | Dust protected | Continuous immersion | Underground enclosures |

| IP59 | Dust protected | Hot jets | Heavy industry enclosures |

| IP60 | Dust-tight | No water protection | IT racks in dusty areas |

| IP61 | Dust-tight | Drips (vertical) | Specialist housings |

| IP62 | Dust-tight | Drips at 15° | Rare |

| IP63 | Dust-tight | Sprays | Electronics in washdown areas |

| IP64 | Dust-tight | Splashes | Outdoor sockets |

| IP65 | Dust-tight | Jets | Factory enclosures, Rittal steel cabinets |

| IP66 | Dust-tight | Powerful jets | Food/beverage plants, Safybox GRP boxes |

| IP67 | Dust-tight | Temporary immersion | Underground junction boxes |

| IP68 | Dust-tight | Continuous immersion (conditions agreed) | Submersible pumps, pit housings |

| IP69 | Dust-tight | High-pressure hot jets (IEC) | Food/pharma machinery |

| IP69K | Dust-tight | High-pressure hot jets (DIN/ISO) | Dairies, abattoirs, heavy vehicles |

IP69 vs IP69K

IP69 and IP69K both describe enclosures designed to withstand extreme washdown, but they are defined in different standards and tested under slightly different conditions.

IP69 (IEC 60529)

- Defined by the International Electrotechnical Commission (IEC) under the IEC 60529 standard.

- Test uses high-pressure, high-temperature water jets.

- The enclosure is sprayed from multiple directions to confirm that no water penetrates.

- Commonly applied in industrial, food, and pharmaceutical settings.

Example: IP69 stainless steel junction box used in cleanrooms and food production facilities.

IP69K (DIN 40050-9 / ISO 20653)

- Originated in Germany under the DIN 40050-9 standard, from the Deutsches Institut für Normung (DIN), the German Institute for Standardisation.

- Later adopted internationally as ISO 20653, developed by the International Organization for Standardization (ISO).

- The test is more demanding than IEC’s IP69:

- Water heated to about 80 °C

- Jet pressure of 80–100 bar

- Flow rate of 14–16 litres per minute

- Spray applied from 0°, 30°, 60°, and 90° angles

- Very close spray distance of 100–150 mm

- Originally created for automotive and heavy-duty vehicles, where equipment must endure close-range hot washdowns.

Example: IP69K stainless steel control cabinet installed in dairies or abattoirs for hygiene compliance.

Comparison Table

| Feature | IP69 (IEC 60529) | IP69K (DIN 40050-9 / ISO 20653) |

|---|---|---|

| Standard body | IEC (International Electrotechnical Commission) | DIN (German Institute for Standardisation), adopted as ISO 20653 |

| Test purpose | General industrial washdown | Automotive and heavy-duty washdown |

| Water temperature | Hot, but not strictly defined | ~80 °C |

| Pressure | High pressure (varies) | 80–100 bar |

| Flow rate | Not strictly defined | 14–16 L/min |

| Spray distance | Moderate | 100–150 mm |

| Spray angles | Multiple directions | 0°, 30°, 60°, 90° |

| Typical use | Food, pharma, hygiene plants | Vehicles, dairies, abattoirs, high-hygiene industries |

What is an IK Rating?

An IK Rating, also known as an Impact Protection Rating, describes how well an electrical enclosure protects its contents from impacts. Unlike IP ratings - which address protection from dust and water - IK ratings focus solely on physical durability. These ratings range from IK00 (no protection against a big hammer) to IK10 (very high impact resistance against a big hammer), with IK11 (50 J) added more recently. Like a Spinal Tap volume dial.

Why IK Ratings Matter

Electrical equipment in public, industrial, or vandal-prone areas needs a certain level of toughness. For example, a car park junction box may only need IK06, while a prison facility or unruly nursery might require IK10.

IK Ratings Explained (0–10)

Here is how each IK level translates into real-world impact resistance:

| IK Code | Impact Energy (Joules) | Equivalent Test | Typical Application |

|---|---|---|---|

| IK00 | None | – | Indoor, secure areas |

| IK01 | 0.14 J | 200 g × 7 cm | Negligible impact areas |

| IK02 | 0.20 J | 200 g × 10 cm | Lighting fixtures |

| IK03 | 0.35 J | 200 g × 14 cm | Low-risk industrial zones |

| IK04 | 0.50 J | 200 g × 20 cm | Indoor machines |

| IK05 | 0.70 J | 200 g × 28 cm | Warehouses |

| IK06 | 1 J | 500 g × 20 cm | Public corridors |

| IK07 | 2 J | 500 g × 40 cm | Outdoor enclosures |

| IK08 | 5 J | 1.7 kg × 29.5 cm | Industrial zones |

| IK09 | 10 J | 5 kg × 20 cm | Heavy-impact areas |

| IK10 | 20 J | 5 kg × 40 cm | Vandal-prone public facilities |

| IK11 | 50 J | Extended test level | Security and transport hubs |

Testing ensures that an enclosure maintains its structural integrity and continues to provide its rated level of protection even after repeated impacts.

IK vs IP: Knowing the Difference

- IK Rating = impact resistance (mechanical protection)

- IP Rating = ingress protection (against dust and water)

Both systems complement each other. In a public or industrial setting, you might choose an enclosure that is rated both IP66 and IK10, ensuring it's dust/water sealed and robust against knocks or vandalism. Or mermaid attacks.

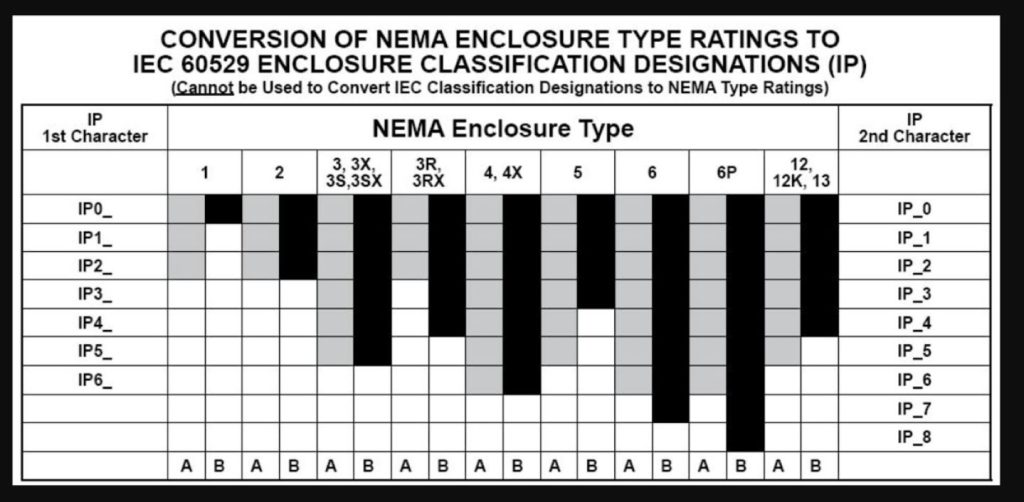

NEMA Ratings vs IP Ratings

What is a NEMA Rating?

NEMA stands for the National Electrical Manufacturers Association, a US-based organisation that defines enclosure standards under NEMA 250.

Unlike IP ratings, NEMA ratings don’t just focus on solids and water. They also cover:

- Corrosion resistance

- Construction details

- Gasket integrity

- Protection against ice formation

- Indoor vs outdoor suitability

NEMA ratings are most widely used in North America, but many enclosures in Europe are also dual-marked with both IP and NEMA equivalents.

Comparison Table

| NEMA Rating | Closest IP Equivalent | Description |

|---|---|---|

| NEMA 1 | IP10 / IP20 | Basic indoor protection against contact and limited dust. |

| NEMA 3 / 3R | IP54 | Outdoor enclosures, rain and sleet resistant. |

| NEMA 3S | IP54 / IP55 | Outdoor use with moving parts operable when ice-laden. |

| NEMA 4 | IP66 | Indoor/outdoor use, protection against hose-directed water and windblown dust. |

| NEMA 4X | IP66 + corrosion resistant | Like NEMA 4, but adds resistance to corrosion (e.g. stainless steel). |

| NEMA 6 | IP67 | Submersible, temporary immersion in water. |

| NEMA 6P | IP68 | Submersible, prolonged immersion in water. |

| NEMA 12 / 12K | IP52 / IP54 | Indoor, protects against dust, dirt, dripping non-corrosive liquids. |

| NEMA 13 | IP54 | Indoor, oil-tight and dust-tight. |

Note: These are approximate equivalents, since NEMA and IP use different test methods. An enclosure may pass one rating without being formally tested for the other.

Practical Example

- A Rittal stainless steel NEMA 4X enclosure not only provides IP66 protection (dust-tight and powerful water jets), but also guarantees corrosion resistance—ideal for food, beverage, and marine applications.

- A nVent Hoffman NEMA 12 cooling unit protects against dust and dripping oil, roughly equivalent to IP54, but tested for oil exposure as well.

- A Safybox GRP enclosure rated IP66 may not carry a NEMA mark, but in practice it offers similar performance to NEMA 4 for dust and washdown protection.

Choosing Between Materials

The material of your enclosure is just as important as the IP or IK rating. Even the best-sealed housing can fail if the material cannot withstand the environment it is placed in. Here’s how to decide between stainless steel, mild steel, and GRP, with product examples available from LED Controls.

Stainless Steel Enclosures

Best for: high-temperature washdown, hygiene-critical industries, coastal or marine sites.

- Why stainless?

Stainless steel offers excellent resistance to corrosion, even in environments exposed to saltwater, cleaning chemicals, or food-processing fluids. It also tolerates extreme temperature changes and aggressive washdowns. Smooth surfaces make it easy to clean, which is essential for hygienic applications. - Where it excels:

Food and beverage plants, pharmaceutical production, dairies, abattoirs, chemical plants, and coastal installations. - Examples:

- nVent Hoffman AFS stainless steel wall enclosures (IP66) – sloping roof and sealed gaskets, designed for tough industrial cleaning regimes.

- Rittal Premium Panel (IP69K) – purpose-built for high-pressure hot washdowns in food and pharma facilities.

Mild Steel Enclosures

Best for: indoor control panels, machine housings, and light outdoor use where corrosion risks are low.

- Why mild steel?

Mild steel is strong, cost-effective, and easy to customise. Powder coatings or paint finishes give extra durability, but it is less resistant to corrosion compared with stainless steel or GRP. - Where it excels:

Factories, workshops, IT rooms, and electrical control rooms where dust protection and basic water resistance are needed but full washdown or chemical exposure is unlikely. - Examples:

- nVent MAS mild steel wall enclosures (IP55) – versatile enclosures for industrial panels and machine controls.

- Rittal AE Compact enclosures (IP54–IP55) – proven small enclosures for electronics and controls in protected environments.

- Contact LED Controls for further recommendations.

GRP (Glass-Reinforced Polyester) Enclosures

Best for: lightweight, non-conductive, and corrosion-proof requirements.

- Why GRP?

GRP is non-metallic, which makes it naturally resistant to corrosion, UV, and many chemicals. It is also non-conductive, offering electrical insulation where metal enclosures are not suitable. GRP is lighter than steel, which helps with installation and reduces load on mounting surfaces. - Where it excels:

Utilities, coastal locations, chemical plants, outdoor distribution boards, renewable energy sites, and underground installations. - Examples:

At a Glance: Which Material Should You Choose?

| Material | Best for | Example Product on LEDControls |

|---|---|---|

| Stainless Steel | High-temperature washdown, hygiene-critical applications, coastal / marine sites | Rittal Compact AE1012.600 Stainless Steel Enclosure, IP66 / NEMA 4X – marine-grade 316L, rounded edges, hygienic finish. |

| Mild Steel / Painted Steel | General indoor and light outdoor use where corrosion is not severe | Rittal Baying enclosure system VX8806.580 Sheet Steel, IP66 / NEMA 4 – offers strong water/dust protection with steel structure. |

| GRP (Glass-Reinforced Polyester) | Situations needing lightweight, corrosion-free, non-conductive material; coastal, chemical exposure, electrical insulation | Safybox BRES-325 GRP Enclosure, IP66 / IK10 – compact GRP with high protection. Safybox BRES-64 GRP Enclosure, IP66 / IK10 – larger GRP housing for harsher conditions. |

Selecting the Right IP Rating for Your Application

Choosing the correct enclosure involves understanding your environment, matching the most demanding scenario, and selecting the right materials and accessories. Here’s a step-by-step guide with product examples stocked by LED Controls.

1. List Your Hazards

Identify the environmental risks, both everyday and extreme conditions:

2. Match the Worst Credible Case

Always design for the harshest credible environment:

| Application | Recommended IP rating | nVent example | Rittal example | Safybox example |

|---|---|---|---|---|

| Cleanroom or indoor panels | IP20–IP40 | nVent Hoffman DPCP polycarbonate terminal box, IP67 (exceeds) | Rittal TS IT server/network enclosure, IP55 (exceeds) | Safybox CA-32S GRP junction box, IP66 (exceeds) |

| Outdoor lighting or sockets | IP44–IP55 | nVent Hoffman MAS wall-mounted enclosure, IP55 | Rittal AE compact sheet-steel enclosure, IP54–IP66 | Safybox CA-44AS GRP junction box, IP66 (exceeds) |

| Factory washdown areas | IP65–IP66 | nVent Hoffman ASR stainless wall-mounted enclosure, IP66 | Rittal VX SE stainless steel, IP66 / NEMA 4X | Safybox BRES-64 GRP enclosure, IP66 |

| Food and beverage processing | IP69 / IP69K | nVent Hoffman SSTB 316 stainless terminal box, IP66 (nearest stocked; IP69K available on request) | Rittal VX SE stainless steel, IP66 / NEMA 4X (Hygienic Design series up to IP69K) | Safybox BRES GRP enclosures, IP66 (used outside washdown zones) |

3. Check Materials and Accessories

An IP rating is only reliable if all components match the enclosure rating.

| Brand | Accessory type | Example Product |

|---|---|---|

| nVent | Vortex coolers and fan units (IP54/IP55) | nVent Hoffman TL4001-4W LED enclosure light, 4W 230V (IP54) |

| Enclosure lighting (IP20–IP55) | nVent Hoffman TL1200 LED enclosure light, 8W 230V (IP20/54) | |

| Rittal | RiLine busbar systems with sealed entry points | Rittal RiLine60 busbar system, 60 mm busbar supports |

| Cable glands, hinges, and lock systems | Rittal SZ cable gland M20, IP68 | |

| Safybox | Compatible GRP accessories: panels, bases, gland plates | Safybox BRES mounting plate, for GRP enclosures |

4. Consider Operation During Test

If the equipment runs during washdown:

| Suffix | Meaning | nVent example | Rittal example | Safybox example |

|---|---|---|---|---|

| M | Tested while moving (equipment operating during water test) | Motors and drives in nVent hygienic stainless IP69K enclosures may require M rating | – | – |

| S | Tested while stationary (equipment not operating during water test) | – | Rittal TS IT cabinets, IP55 often validated with S | Safybox BRES GRP enclosures, IP66 are mostly static, so S applies |

| W | Tested under specific weather conditions (rain, UV, atmospheric exposure) | nVent Hoffman MAS outdoor wall-mounted IP55 can be specified for outdoor use | Rittal VX SE stainless, IP66 / NEMA 4X suited for harsh outdoor weather | Safybox BRES-83 GRP enclosure, IP66 widely used in coastal and exposed sites |

5. Balance Protection with Practicality

Higher ratings are not always necessary.

| Factor | nVent example | Rittal example | Safybox example |

|---|---|---|---|

| Heat dissipation | nVent Hoffman cooling & lighting units help balance high IP protection and improve airflow | Rittal climate control accessories integrate directly with sealed enclosures | Safybox GRP enclosures can be specified with ventilation kits for airflow |

| Weight and cost | nVent Hoffman stainless enclosures cost more but last longer in hygiene and marine sites | Rittal VX SE stainless IP66 higher upfront cost, long lifespan | Safybox BRES GRP IP66 enclosures are lighter, cheaper, and corrosion-free |

Quick Reference Table

| Application | Recommended Rating | Product Example |

|---|---|---|

| Indoor switchgear | IP20–IP40 | Rittal TS IT network/server enclosure, IP55 (exceeds) |

| Outdoor sockets/lighting | IP44–IP55 | nVent Hoffman MAS wall-mounted steel enclosure, IP55 |

| Factory washdown | IP65–IP66 | nVent Hoffman ASR stainless wall-mounted enclosure, IP66 or Rittal VX SE stainless, IP66 / NEMA 4X |

| Underground/flood risk | IP67–IP68 | nVent Hoffman MGRP polyester terminal box, IP67 |

| Food, beverage, pharma | IP69 / IP69K | Contact LED Controls for IP69/K recommendations. |

| Cooling internal electronics | IP54 / IP55 | nVent Hoffman TL4001-4W LED enclosure light, IP54 or Rittal climate control accessories |

Frequently Asked Questions

Is IP68 “better” than IP66?

Not automatically. Both offer full dust protection (first digit “6”), but the difference lies in water resistance. IP66 withstands powerful water jets, making it ideal for washdown. IP68 is designed for continuous immersion, with depth and duration specified by the manufacturer. If your application may face both immersion and jetting, you’ll need to either select a product that meets both or reconsider the installation method.

Do I need IP69/IP69K for food and beverage environments?

Yes, if hot, close-range washdowns are routine. The 9/9K tests were created for hygiene-critical industries, confirming resistance to near-boiling water under high pressure. If your process only involves light cleaning or splashing, IP66 is often sufficient. Always align the enclosure rating with your hygiene or audit requirements.

What do optional letters like “W,” “M,” or “S” really mean?

These suffixes describe the test conditions, adding clarity to the rating. W means the product has been tested under weather conditions like rain or UV exposure. M means the water test was done while the equipment was running or moving. S means it was tested while stationary. This detail can be crucial for auditors and ensures you choose a rating that reflects real-world operation.

Does a higher IP number always mean better protection?

Not necessarily. The two digits measure different things: the first digit is solids protection, the second is liquids. A higher liquid digit (e.g. 8) doesn’t automatically cover jetting resistance (6). For instance, IP67 is excellent for immersion but not guaranteed against pressure washing, while IP66 is superb against jets but not immersion.

What if a rating is listed as IPX7 or IP6X?

The X means the enclosure wasn’t tested for that aspect. IPX7 confirms immersion protection but gives no assurance against dust. IP6X confirms dust-tight sealing but doesn’t claim any water resistance. This doesn’t necessarily mean the enclosure will fail in untested conditions, but you cannot rely on it without formal testing.

Can an IP rating alone guarantee my enclosure’s longevity?

No. The rating shows resistance to ingress, but long-term performance depends on materials, gasket quality, UV stability, corrosion resistance, and maintenance. For example, a stainless steel IP66 enclosure in a coastal site will last far longer than a painted mild steel enclosure with the same rating. Always consider both IP protection and the enclosure’s build materials.

How does IP compare to NEMA ratings?

IP and NEMA are related but not identical systems. IP ratings are international and focus only on solids and liquids. NEMA ratings, used mainly in the US, also include tests for corrosion, icing, oil, and coolant ingress. Some IP and NEMA ratings are roughly equivalent, but they are not interchangeable. If you’re working in a North American context, check the NEMA rating; in Europe or internationally, IP is the standard.

Quick reference: all possible IP ratings and attributes

Solids (first digit): 0, 1, 2, 3, 4, 5, 6 or X (unspecified)

Water (second digit): 0, 1, 2, 3, 4, 5, 6, 7, 8, 9 (IEC hot jets) or X

Common optional letters: A, B, C, D (access probes); H; M; S; W

Automotive variant: 9K (DIN/ISO high-temperature, high-pressure jets)

IP Rated Options from LED Controls

LED Controls stock a wide range of enclosures that fit the various IP ratings. We can recommend an enclosure with the right IP rating, materials, and accessories for whatever your application may be. Here's a few examples of what we have available:

Any more questions, just get touch with the IP rating experts at LED Controls for a personal enclosure recommendation:

01706 242050

[email protected]

www.ledcontrols.co.uk