We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

LED Controls Blog

WAGO Compact Controller 100: All-in-One PLC from LED Controls

January 27, 2026 What is the WAGO Compact Controller 100? If your automation system calls for reliable control, strong communications and flexible I/O -... Read full

Breakdown Rescue: Factory Automation Emergency Delivery from LED Controls Ltd

January 22, 2026 When an important piece of equipment fails, every second counts. You need to get your operation moving again as quickly... Read full

Finder 72 Series Float Switches – Reliable Liquid Level Control

January 20, 2026 What are Finder 72 Series float switches? Finder 72 Series float switches are mechanical level switches that turn pumps or alarms... Read full

ABB OT and OT PLUS Disconnectors: The LED Controls Guide

January 15, 2026 What are ABB OT Disconnectors? ABB OT Disconnectors are manually operated switch-disconnectors designed to isolate your electrical circuits visibly and safely.... Read full

Danfoss FC51 to be Replaced by iC2 Micro Drive in 2026

January 13, 2026 The Danfoss VLT® Micro Drive FC51 has been a top choice for engineers and panel builders across a wide range... Read full

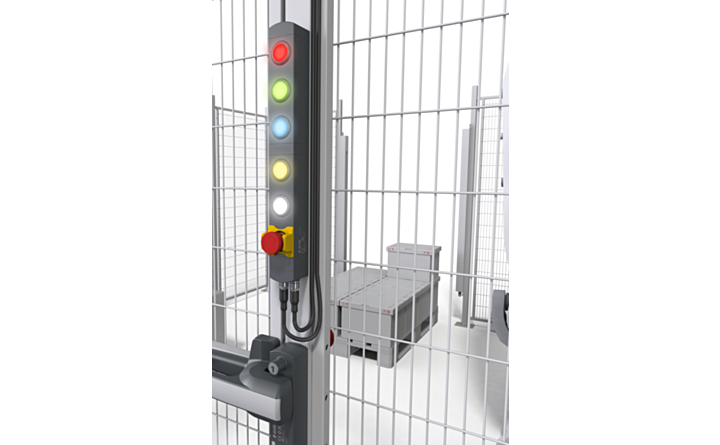

Meet the Pizzato BN Series – Smart IO-Link Control Units Now at LED Controls

January 08, 2026 LED Controls are thrilled to welcome Pizzato BN Series IO-Link control device units to our expanding product range as part... Read full

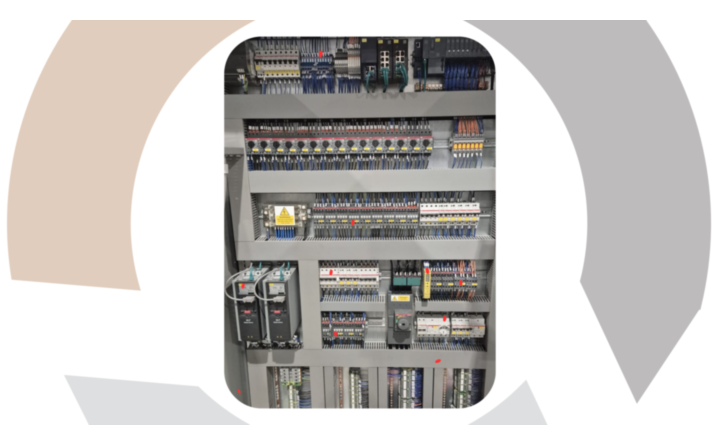

LED Controls: Your Complete Control Panel Solution

January 06, 2026 ... Read full

LED Controls in 2025: a year of products, partnerships and practical automation insight

December 23, 2025 2025 has been a big year for LED Controls, and our blog has expanded accordingly. We've covered a wide range... Read full

ABB Sentry Safety Relays at LED Controls

December 18, 2025 What is an ABB Sentry Safety Relay? The ABB Sentry Safety Relay range is designed to stop machines quickly and reliably... Read full

Finder 12 Series Time Switches at LED Controls

December 16, 2025 Simple, reliable control for lighting and electrical loads Finder 12 Series Time Switches are reliable time-based controllers that automate lighting and... Read full

Danfoss FC 102: The HVAC Engineer's Drive

December 11, 2025 The Danfoss FC 102 (VLT® HVAC Drive) is one of the most widely used variable speed drives in building services.... Read full

ABB Overloads: Thermal vs Electronic Protection Explained

December 09, 2025 ABB Overloads protect motors against overheating, phase loss and sustained overcurrent. They form a vital part of any motor starter... Read full

Pizzato CS AM Series – Advanced Motor Safety Now at LED Controls

December 04, 2025 Intelligent Motor Monitoring with Pizzato We’re excited to welcome Pizzato to the LED Controls roster of trusted manufacturers, and introduce you... Read full

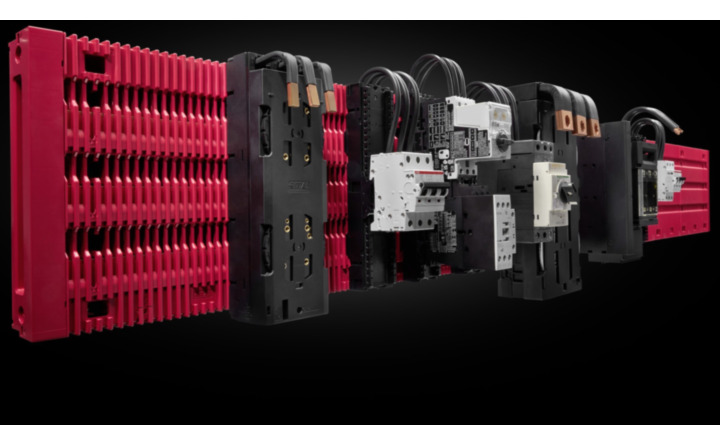

Rittal RiLineX: The Future of Busbar Power Distribution at LED Controls

November 27, 2025 Power distribution is changing fast, but the new Rittal RiLineX busbar system is here to keep you connected. Now available... Read full

MCB vs RCD: What’s the Difference?

November 25, 2025 If you’ve ever looked inside a consumer unit or worked on a control panel, you’ve probably seen both an MCB... Read full

What is EMC Filtration? - Electromagnetic Compatibility with Danfoss Drives

November 20, 2025 What is EMC Filtration? EMC filtration in factory automation and industrial control refers to managing electromagnetic interference (EMI) so that electrical... Read full

ABB AF Contactors and Overload Relays - The LED Controls Guide

November 18, 2025 Electric motors keep most industrial and commercial processes moving. If your business is running pumps, fans, compressors or conveyors, you're... Read full

What Is a PID Controller?

November 13, 2025 A PID controller is an industrial automation control system that continually adjusts an output to keep a process variable -... Read full

Get Smart Control with the FINDER OPTA Programmable Logic Relay

November 11, 2025 What is Finder OPTA? The Finder OPTA is not your average relay. A traditional relay is an electrically operated switch that... Read full

Driving Logic: Built-In PLC Functionality in Danfoss Drives

November 06, 2025 Traditionally, Variable Speed Drives (VSDs) manage motor speed and torque, while Programmable Logic Controllers (PLCs) take care of the decision-making... Read full