We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What is EMC Filtration? - Electromagnetic Compatibility with Danfoss Drives

What is EMC Filtration?

EMC filtration in factory automation and industrial control refers to managing electromagnetic interference (EMI) so that electrical and electronic systems can operate without disruption.

What Does EMC Stand For?

EMC stands for Electromagnetic Compatibility. This means the ability of equipment to function correctly in its electromagnetic environment without generating interference that affects nearby systems.

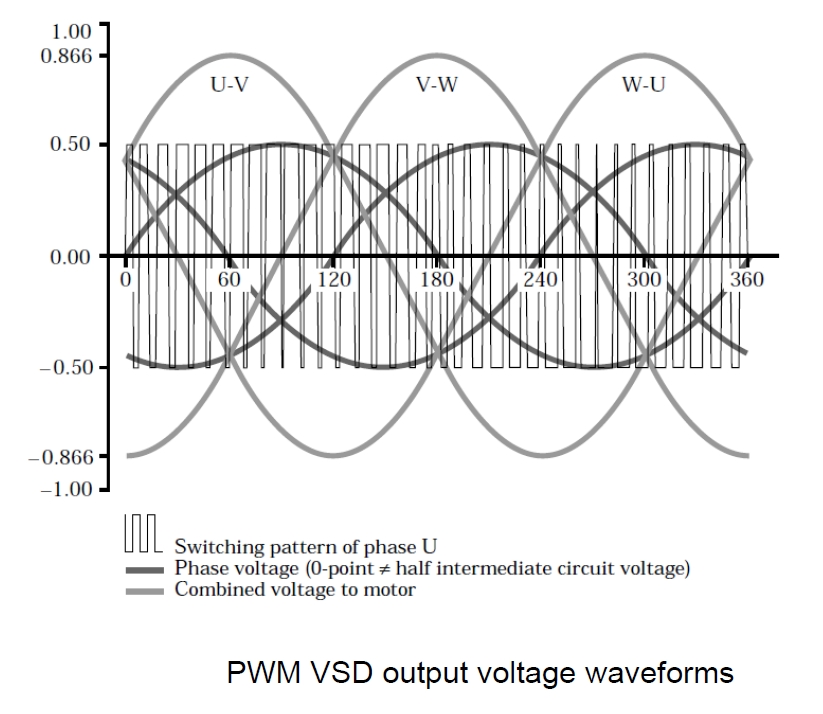

In industrial automation, high-frequency switching components found in variable speed drives (VSDs), PLCs, and servo systems can produce electrical noise. Without suitable filtration, this noise can cause malfunctions, communication errors, and premature component wear.

What Does “Noise” Mean?

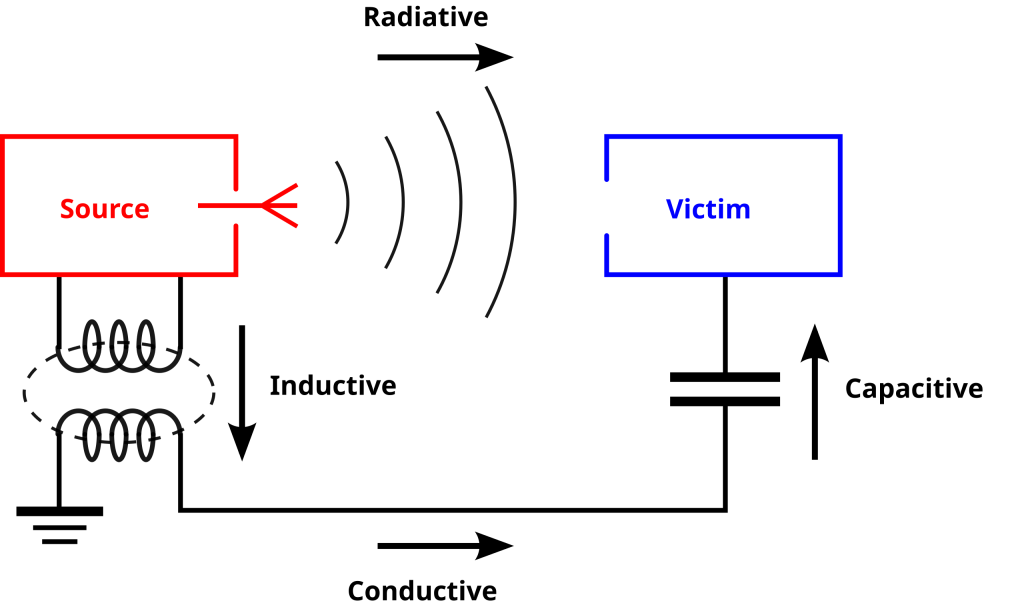

Noise refers to EMI - unwanted or random electrical signals that can interfere with your system operation. It may originate inside a device (for instance, a drive’s switching circuits) or externally (from power lines, radio transmitters, or adjacent machinery). In a factory setting, noise can travel along power cables, through control wiring, or radiate through the air.

Effective EMC filtration stabilises voltage and current, protecting connected equipment and ensuring reliable performance.

What is RFI?

RFI, or Radio Frequency Interference, is a type of high-frequency electrical noise that typically occurs between 10 kHz and 300 GHz. It is often caused by fast-switching electronic components such as those in drives and power supplies. In industrial environments, RFI can result in data errors, false sensor readings, and communication faults.

How EMC Filtration Works

EMC filters are fitted at a system’s power input to block unwanted high-frequency signals while allowing standard 50/60 Hz power through. Using capacitors and inductors, they tackle two types of interference:

- Differential mode noise – between live and neutral conductors.

- Common mode noise – between conductors and earth (ground).

By controlling both, EMC filters help maintain stable, interference-free power and data communication.

Why EMC Filtration Matters in Factory Automation

In industrial automation, dependable communication and precision control are vital. EMC filtration:

- Prevents false triggering of sensors and control inputs.

- Minimises data and signal errors across networks.

- Extends component lifespan by reducing electrical stress.

- Helps systems meet the EU EMC Directive (2014/30/EU).

What are H Ratings and C Ratings?

What C Ratings Mean

C ratings are EMC compliance limits derived from IEC 61800-3. Drives achieve a rating depending on how much EMI they emit.

- C1 - The tightest limits. Low emissions. Suitable for residential, commercial and public networks. Only drives with strong internal filtering and good installation can meet C1.

- C2 - Still strict, but intended for professional installation in commercial or industrial areas. Many filtered Danfoss drives fall into this category.

- C3 - For industrial sites. Emission limits are more relaxed. Unfiltered drives usually fall here unless fitted with an external EMC/RFI filter.

- C4 - For very high power industrial systems. Only applies to larger installations, not most common low-voltage drives.

What H Ratings Mean

H ratings appear in the Danfoss drive type code. They indicate what EMC/RFI filter hardware is built into the drive.

- H1 - Built-in EMC/RFI filter providing strong suppression. Often capable of C1 or C2 when installed correctly.

- H2 - No EMC filter fitted. Usually meets C3 unless an external filter is added.

- H3 - Enhanced EMC filter on certain smaller frame sizes. Typically capable of C1 or C2.

- H4 -Integrated EMC filter (common on HVAC FC-101 models). Usually supports C2 and, in some cases, C1.

- H5 - Higher-spec EMC filter option used on certain specialised or marine-approved variants.

- HX - No EMC filter fitted, often on higher-voltage models. Intended for industrial C3 environments.

How H and C Ratings Relate

The type of filter fitted (H rating) directly affects the emission level the drive can realistically meet (C rating). Drives with built-in filters achieve stricter limits. Drives without filters default to industrial environments unless external filters are added.

EMC Filtration Products from Danfoss at LED Controls

Danfoss Drives incorporate robust RFI and EMC filtration into many VLT and Vacon models, helping maintain clean, stable operation even in electrically demanding environments. By suppressing high-frequency interference at the source, Danfoss solutions support reliable communication, protect sensitive equipment, and keep systems compliant with EMC standards.

| H Rating | Filter Type | Typical C Rating | Explanation | Relevant Danfoss Products from LED Controls |

|---|---|---|---|---|

| H1 | Built-in EMC/RFI filter | C1 or C2 | Strong internal suppression suitable for commercial, HVAC, and mixed-use environments. | VLT FC-101 (131L9869) – 11 kW HVAC drive with Class A1/C2 filtering. VLT FC-101 (131L9866) – 4 kW drive with built-in EMC filter. |

| H2 | No EMC filter fitted | C3 | Industrial emissions only. External EMC filter required to reach C1 or C2. | iC2 Micro – Standard Variants – unfiltered models intended for industrial use. |

| H3 | Enhanced EMC filter (small frames) | C1 or C2 | Higher-performance filtering for smaller frame sizes and tighter EMC requirements. | iC2 Micro – Filtered Variants – filtered versions capable of lower emission categories. |

| H4 | Integrated EMC filter (HVAC models) | C2, sometimes C1 | Designed for building services and HVAC where lower emissions are essential. | VLT FC-101 (131L9794) – 0.75 kW HVAC drive with integrated RFI suppression. |

| H5 | Higher-spec EMC filter | Varies | Specialised or marine-approved EMC filtering for demanding environments. | Available on selected VLT AutomationDrive FC-series (model-specific; contact LED Controls for details). |

| HX | No EMC filter fitted | C3 | Intended for industrial networks; external filtering can be added for lower emission categories. | iC7 Automation Drive – certain variants supplied without internal EMC filter. |

As a Danfoss Authorised Partner, LED Controls' expert sales team are on hand to help you choose the right Danfoss EMC-compliant solution for your installation. So get in touch if you're ready to cut through the noise:

01706 242050

[email protected]

ledcontrols.co.uk