We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What is Condition-Based Monitoring? With Danfoss Drives

Time is money, especially in industrial environments where unexpected breakdowns can lead to costly production delays. That’s why we recommend Condition-Based Monitoring (CBM) with drive systems from Danfoss to give you a smarter, more efficient method of maintenance monitoring.

Condition-Based Monitoring does exactly what it says on the tin: Your drives keep tabs on the running condition of your system in real time, and report or react according to preset parameters. At LED Controls, we’re proud to be a Danfoss Authorised Partner which means we can deliver drives with this advanced monitoring feature designed to reduce downtime, improve performance and extend your equipment life.

How Condition-Based Monitoring Works

1. Establishing a Baseline

CBM begins by identifying what “normal” looks like for your system. This baseline represents the level of your equipment’s standard operating conditions, such as motor vibration, temperature, or load.

There are several ways to establish this baseline:

- Manual Baseline – Technicians input known parameters based on experience.

- Baseline Run – A sweep through the speed range is performed during commissioning to capture operating data.

- Online Baseline – The system learns normal values during live operation, ideal when a baseline run isn’t practical.

However you define it, your baseline gives your drive a set standard to compare real-time data against and report any deviations.

2. Defining Thresholds

After your baseline is set, thresholds are configured to determine when warnings, alarms or even shutdowns should trigger. These thresholds can be:

- Absolute values – Based on known limits, e.g. ISO vibration standards

- Offset values – Custom margins added to the baseline

- Factor-based thresholds – A percentage above the baseline, e.g. 150%

For intuitive status monitoring, a traffic light system can be used:

- 🟢 Green – All systems operating normally

- 🟡 Yellow – Early warning: plan maintenance soon

- 🟠 Orange – Critical warning: action needed

- 🔴 Red – Alarm: system shutdown or fault active

You can check your alerts via drive displays, fieldbus, digital outputs, or integrated with cloud or SCADA systems.

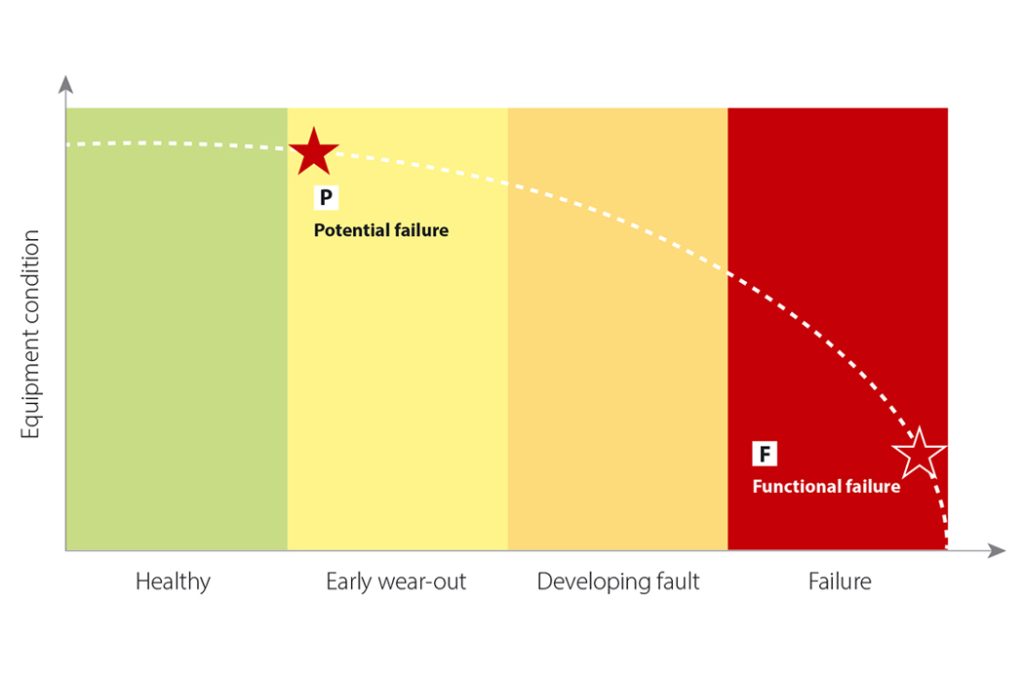

3. Continuous Monitoring

Once set up, CBM continuously compares live sensor data to the set thresholds. So if a deviation goes longer than your preset time limit (filtering out temporary spikes), a warning or alarm is issued, which gives you time to act before failure occurs.

Key Benefits of Condition-Based Monitoring

- Reduce Unplanned Downtime

Detect issues early and prevent sudden equipment failures that disrupt your production. - Extend Equipment Life

Targeted maintenance prevents wear from going unnoticed and avoids unnecessary over-servicing. - Improve Maintenance Efficiency

Perform maintenance as needed based on actual machine conditions, not at fixed intervals. - Lower Operating Costs

Fewer emergency repairs, reduced labour time, and optimised spare part usageadd up to long-term savings. - Boost Safety and Compliance

Real-time alerts help prevent accidents, improve diagnostics, and ensure your system's up to code. - Simplify Data Integration

Get real-time insight through local drive displays, fieldbus systems, or cloud dashboards.

Take the Next Step with LED Controls

CBM transforms maintenance from reactive to proactive, helping you avoid breakdowns, reduce service costs, and keep your operations running at peak efficiency.

Want to know which Danfoss drive is right for your application? Check out the range online or get in touch with LED Controls today. As your friendly neighbourhood Danfoss Authorised Partner, we can help find the perfect bespoke Danfoss Drive configuration to put you in control of your maintenance strategy.

01706 242050

[email protected]

www.ledcontrols.co.uk