We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What is a Residual Current Device? The Complete LED Controls Guide to RCDs

Residual Current Devices (RCDs) are a cornerstone of modern electrical safety in homes and commercial or industrial settings. At LED Controls Ltd, we supply high-quality ABB and Chint RCDs that help protect people, equipment, and property from dangerous electrical faults. But what do RCDs actually do?

What Is an RCD?

An RCD is an electrical safety switch that instantly disconnects a circuit when it detects electrical leakage. This could be caused by faulty equipment, worn wiring or even a person being electrocuted!

How do RCDs Work?

A Balanced Loop

Think of an electrical circuit as a loop: power travels from the supply through live wires into the circuit, through any appliances connected to the circuit, and returns to the source through neutral wires. When a circuit is operating correctly, the current flowing out through the live conductor is exactly equal to the current returning through the neutral conductor. This balanced flow means none of the energy travelling to the appliances on the circuit is leaking out anywhere.

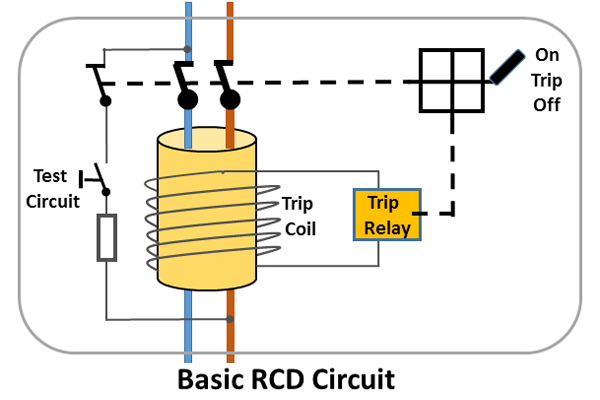

An RCD continuously monitors both conductors using a toroidal current transformer inside its casing. Both the live and neutral wires pass through this doughnut-shaped magnetic core, creating two magnetic fields. When the currents are balanced, these magnetic fields are equal and opposite, so they cancel each other out and everything carries on as normal.

If the Current Leaks...

If something goes wrong - maybe a damaged cable allows current to leak to an earthed metal surface or a person accidentally touches a live wire - some of the current flowing out through the live wire will not return through the neutral. This is called earth leakage. Even a tiny leakage current, typically as low as 30 milliamps (mA) in domestic RCDs, is enough to create a magnetic imbalance inside the toroidal core.

That imbalance induces a small voltage in a secondary winding within the core. This voltage is fed into the RCD’s trip mechanism - an ultra-sensitive relay that mechanically disconnects the circuit. The disconnection happens in under 30 milliseconds, faster than the blink of an eye, which is critical because electricity does more damage the longer you're in contact with it.

Here’s what’s happening in sequence:

- Live current flows from the power source into the circuit.

- Neutral current returns from the load back to the source.

- The RCD measures both flows continuously via the magnetic balance in its core.

- If a leak occurs in the circuit, the neutral current will be less than the live current.

- The trip coil is energised by the induced voltage in the core’s secondary winding.

- The contacts open, physically breaking the circuit and cutting off power.

Safety Benefits

From a safety perspective, this rapid action dramatically reduces the risk of:

- Ventricular fibrillation - essentially a cardiac arrest caused by electric shock.

- Burns from prolonged current flow through the body.

- Electrical fires caused by leakage heating cables or igniting flammable materials.

The genius of the RCD is that it doesn’t need to know where the fault is, only that current is escaping somewhere it shouldn’t. That means it can protect against a wide range of hazards, from faulty appliances to damaged wiring and even accidental contact with live parts.

Types of RCDs and Their Applications

Not all Residual Current Devices are the same. Which you choose depends on what kind of current your system uses, the equipment it powers, and the environment where it's working. To understand why there are different RCD types, it helps to first know that electricity can behave in different ways:

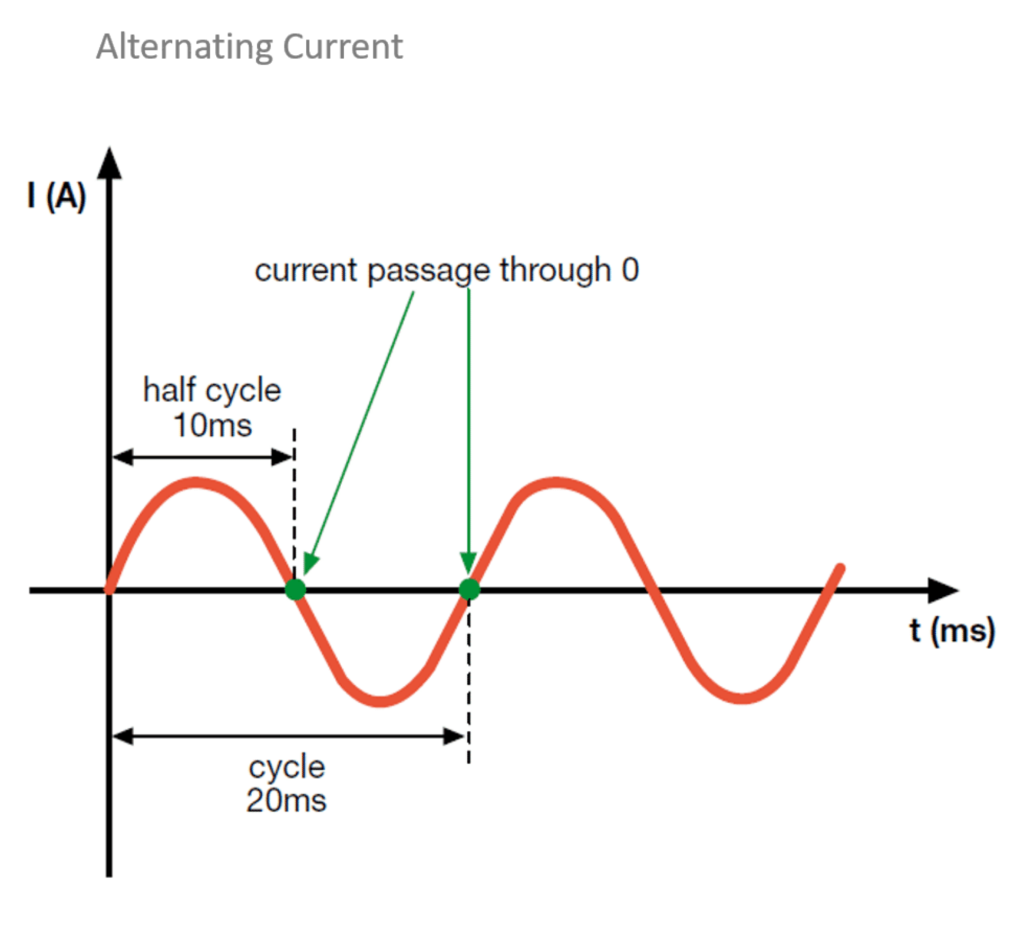

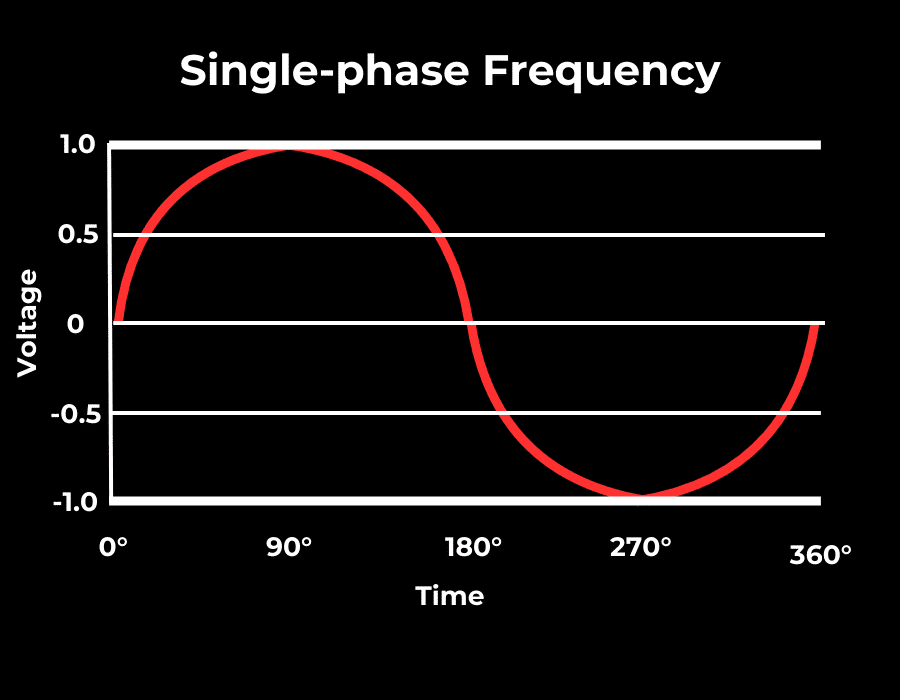

Alternating Current

Alternating Current (AC) is the type of electricity supplied by the national grid and used in most homes and workplaces. In an AC system, the flow of electricity doesn’t just move in one direction, it repeatedly reverses direction at a fixed rate. In the UK, this happens 50 times per second, which is called a frequency of 50 hertz (Hz). What’s actually “alternating” is the polarity of the voltage and the direction of the current.

This back-and-forth motion is produced the same way electricity is generated in power stations: large rotating machines (alternators) spin magnets inside coils of wire, creating a voltage that naturally rises and falls in a smooth wave pattern known as a sine wave. AC is used for power distribution because it’s efficient to generate, easy to transform to higher or lower voltages for transmission and supply, and works well with a wide variety of electrical equipment.

Direct Current

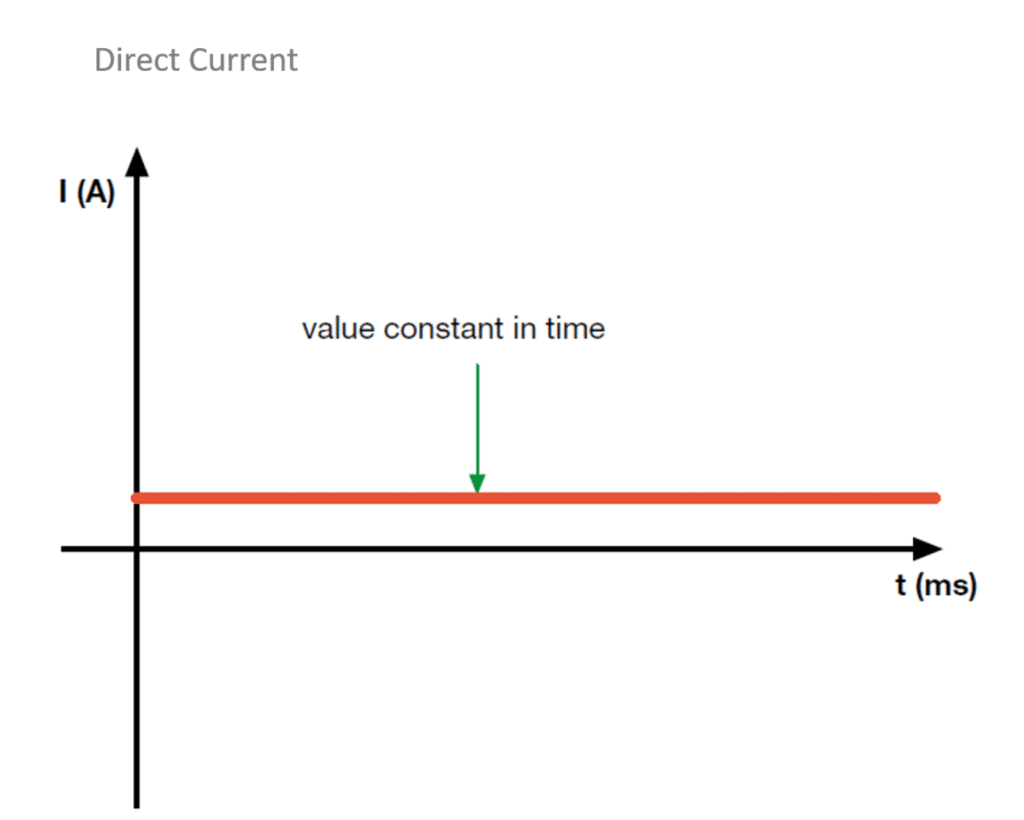

Direct Current (DC) flows in one constant direction, like the power from a battery.

However, in many electronic devices, DC can appear in two forms:

- Pulsating Direct Current (Pulsating DC) is a form of electricity where the flow of charge always moves in the same general direction, like normal direct current, but its strength rises and falls in a repeating pattern. Like water being pumped down a pipe in surges, speeding up and slowing down, but never changing direction. This “pulsating” behaviour often happens when AC power is converted to DC by a process called rectification. In many appliances, this rectified current isn’t perfectly smoothed, so it still has a wave-like variation in voltage and current. Pulsating DC is common in devices with motors, heating elements controlled by electronics, and LED lighting systems.

- Smooth Direct Current (Smooth DC) is a pure, steady flow of electricity in one direction, with no rise-and-fall variation. Imagine that same waterpipe now flowing at a constant speed. Smooth DC is produced by batteries, high-quality power supplies, solar photovoltaic (PV) inverters, and electric vehicle chargers. It’s ideal for sensitive electronics because it delivers a stable voltage without fluctuations.

Why does this matter for RCDs?

Different types of RCDs are designed to detect different types of current leakage. Some older or simpler RCDs can be “blinded” by certain DC leakage currents, meaning they might fail to trip when needed. That’s why it’s important to select the right type of RCD for your installation.

RCD Types – Detection Capability and Applications

| RCD Type | What It Detects | Typical Applications | Why It’s Needed | Limitations | Best For |

|---|---|---|---|---|---|

| Type AC | Alternating current (AC) only | Simple resistive loads – e.g., traditional heaters, incandescent lighting, basic appliances | Suitable for older or simple installations where only AC loads are present | Cannot detect pulsating or smooth DC leakage; unsuitable for modern electronics | Older installations or purely resistive loads |

| Type A | AC + pulsating DC | Homes and light commercial setups with electronics – washing machines, dishwashers, LED lighting, power tools | Detects pulsating DC leakage that can “blind” Type AC devices | Cannot detect smooth DC leakage | Mixed domestic and commercial loads with electronics |

| Type A AP-R (Advanced Performance) | AC + pulsating DC (improved immunity to transients) | Environments prone to nuisance tripping – commercial kitchens, offices, workshops | Filters out harmless transient currents while still tripping on real faults | More expensive than standard Type A | Power-critical sites where interruptions must be minimised |

| Type F | AC + pulsating DC + limited smooth DC (up to ~1kHz leakage) | Appliances with single-phase frequency-controlled motors – washing machines, heat pumps, AC units | Detects high-frequency leakage currents from variable-speed drives | Not suitable for installations with significant smooth DC leakage above rated frequency range | Circuits with modern appliances using frequency-controlled drives |

| Type B | AC + pulsating DC + smooth DC | EV charging points, solar PV systems, industrial machinery, variable-speed drives | Detects smooth DC leakage that standard RCDs cannot sense | More complex and costly | Industrial, renewable, EV charging, transport systems |

| Type B+ | AC + pulsating DC + smooth DC + extended high-frequency range (up to ~20kHz) | Advanced industrial, renewable energy, high-frequency power electronics | Covers the widest range of leakage frequencies for maximum detection | Highest cost; may be over-specified for simple systems | High-end industrial or specialist installations requiring broad-spectrum detection |

Phases and Poles

When choosing an RCD, two more important factors are phases and poles. These affect how your electrical system is wired, how much power it can deliver, and how your RCD will protect it.

Single-Phase or Three-Phase?

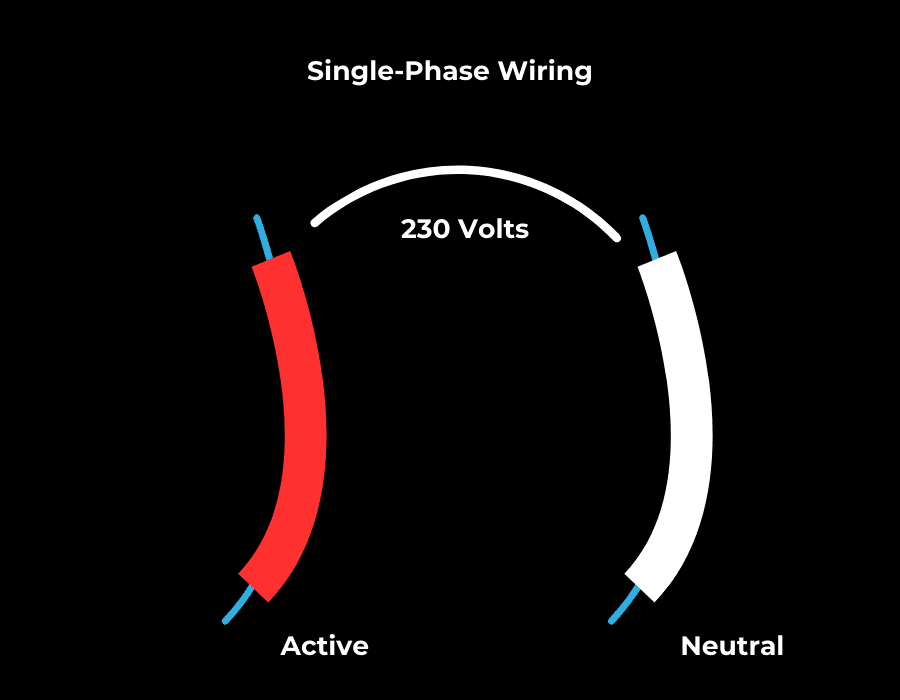

The number of phases indicates how many separate live wires are bringing electricity into your circuit. These “phases” are different parts of the supply that work together to deliver power.

Single-Phase Systems

- What it is: One live wire + one neutral wire.

- Where it’s used: Most homes, small shops, and light commercial setups.

- Why choose it: Perfect for everyday loads like lighting, plug sockets, and small appliances.

- Power capacity: Adequate for typical domestic needs.

- Example: The wiring that runs your TV, kettle, and lights.

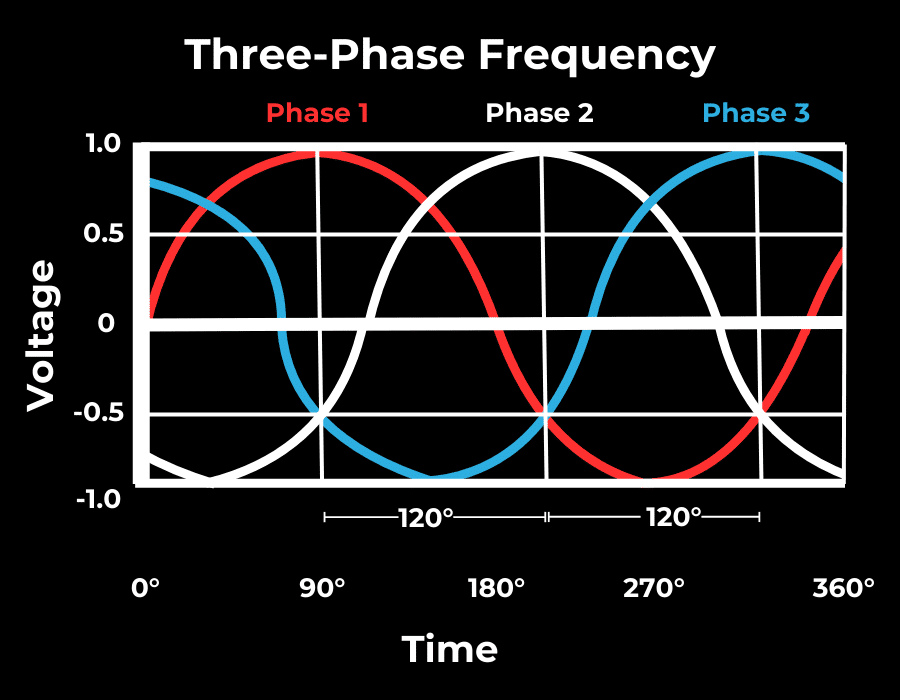

Three-Phase Systems

- What it is: Three live wires, each with its own “wave” of power, plus sometimes a neutral wire.

- Where it’s used: Large houses, commercial buildings, factories, and anywhere with heavy machinery.

- Why choose it:

- Delivers more power without requiring bigger cables.

- Provides a smoother power supply for motors and large equipment.

- Shares the load across three wires for efficiency.

- Example: Industrial motors, commercial HVAC, or large heating systems.

Simple rule:

If you need more power or are running heavy-duty equipment, you might need a three-phase system. For standard household needs, single-phase is usually enough.

RCD Pole Counts and How They Relate to Phases

The pole count on an RCD tells you how many conductors (wires) it can switch off and protect. The type you choose depends on your phase system and whether you also want the neutral disconnected.

Common RCD Pole Types

| Pole Type | Number of Conductors Switched | Typical Use | Related Phase System |

|---|---|---|---|

| SP+N (Single Pole + Neutral) | 1 live + neutral | Single-phase circuits where live is switched and neutral is also isolated | Single-phase |

| DP (Double Pole) | Live + neutral | Single-phase circuits needing complete isolation | Single-phase |

| TP (Triple Pole) | 3 live wires | Three-phase systems without a neutral | Three-phase |

| TP+N (Triple Pole + Neutral) | 3 live wires + neutral | Three-phase systems with a neutral | Three-phase |

| 4-Pole | 3 live wires + neutral | Full isolation in three-phase four-wire systems | Three-phase |

How Phases and Poles Work Together

- Single-phase systems usually use SP+N or DP RCDs, as they only have one live and one neutral wire to protect.

- Three-phase systems require TP, TP+N, or 4-pole RCDs to cover all live wires (and the neutral if present).

- Why this matters: If your RCD doesn’t match your system’s phases, it won’t disconnect all conductors in a fault, leaving parts of the circuit live and unsafe.

In short:

- Phases = how your power is supplied.

- Poles = how many wires your RCD can isolate.

Match the two correctly, and you’ll get proper protection, safe maintenance, and a system that works exactly as it should.

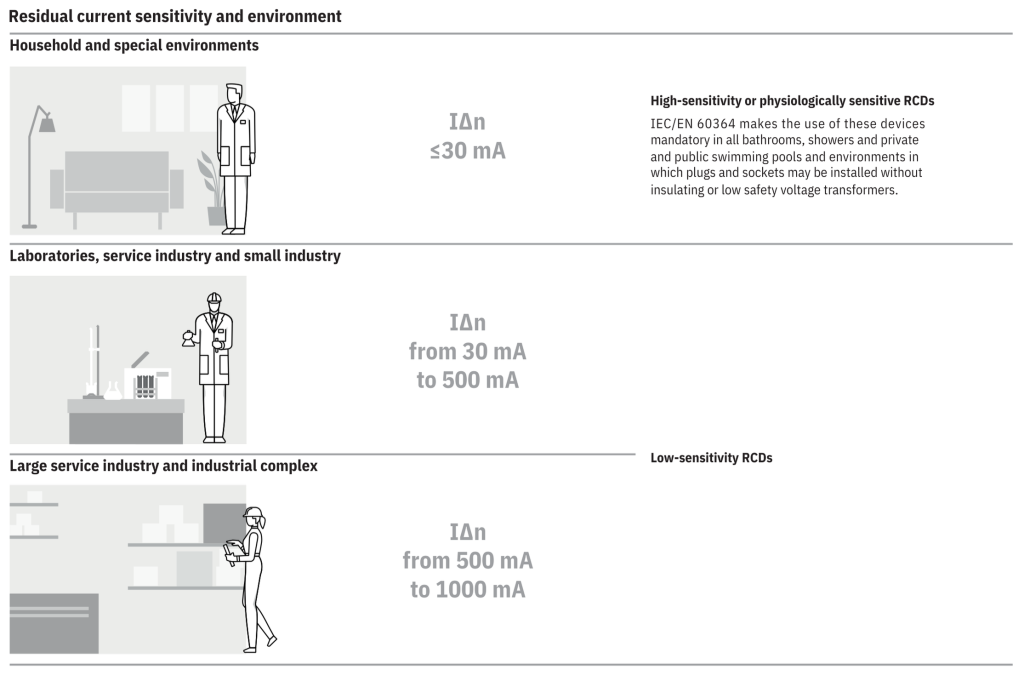

RCD Sensitivity: Understanding mA Ratings

Another key RCD specification is its milliamp (mA) rating, also called its sensitivity. This tells you how much earth leakage current the device will tolerate before it trips. In other words, it’s the “trip threshold”, the point at which the RCD cuts power to protect people and equipment.

Common RCD Sensitivity Levels

| mA Rating | Typical Use | Reason for Use |

|---|---|---|

| 30 mA | General personal protection in homes and workplaces | Detects small leakage currents that could cause harmful electric shocks. The most common rating for socket circuits and domestic installations. |

| 100 mA | Fire protection in certain circuits, or selective protection upstream of 30 mA devices | Less sensitive to small leakage currents, but still trips fast enough to prevent wiring overheating and fire risk. |

| 300 mA | Main incomer protection for large buildings, industrial boards, or agricultural sites | Primarily for fire prevention rather than direct shock protection; allows normal small leakages from large installations without nuisance tripping. |

| 10 mA | Special locations such as medical areas, nurseries, or wet environments | Ultra-sensitive protection where even tiny leakage currents could be dangerous to vulnerable people. |

Why Sensitivity Matters

- Shock protection:

- The human heart can go into fibrillation with currents as low as 30 mA passing through the body.

- A 30 mA RCD is designed to trip quickly enough to minimise this risk.

- Fire prevention:

- Leakage currents as low as 300 mA can cause dangerous heating in wiring over time.

- Higher-rated RCDs (100 mA or 300 mA) are often used for main switch protection to guard against fire risks.

- Avoiding nuisance tripping:

- Large systems naturally have small leakage currents from many devices. Using a 300 mA RCD upstream avoids constant unwanted trips, while smaller downstream RCDs handle personal protection.

How to Choose the Right Sensitivity

- General domestic circuits: 30 mA

- Special care areas: 10 mA

- Upstream protection with selectivity: 100 mA or 300 mA, depending on the risk and regulations

- Industrial or agricultural systems: Often 300 mA at the incomer, with 30 mA protection on final circuits

In short: The mA rating on an RCD is not about how much current your appliances use — it’s about how sensitive the device is to leakage. Choosing the correct rating means balancing safety, fire prevention, and practicality for the type of installation.

Where Are RCDs Required?

RCDs are far more common than many people realise. In fact, if you live in a modern home or work in a well-maintained building, there’s a good chance you’re already protected by one. They’re used anywhere there’s a risk that electricity could find its way to earth through a person or faulty equipment:

- In the Home

- Socket circuits – Many modern wiring regulations require RCDs on socket-outlets, especially those rated at 32A or less.

- Outdoor power – Garden equipment, exterior lighting, and outbuildings all typically need RCD protection.

- High-risk rooms – Bathrooms, utility rooms, and kitchens, where moisture is common, are often covered by dedicated RCD-protected circuits.

- In Commercial Premises

- Offices and retail spaces – RCDs protect socket circuits and portable equipment to reduce the risk to staff and customers.

- Hospitality venues – Kitchens, outdoor dining areas, and entertainment spaces often have additional RCDs for guest safety.

- Maintenance and cleaning points – Anywhere portable appliances are plugged in for service work, especially if water is involved.

- In Industrial and Specialist Environments

- Workshops and factories – Machinery and power tools are commonly supplied via RCD-protected circuits.

- Agricultural sites – Environments with high moisture, animals, and outdoor machinery rely heavily on RCDs to prevent shocks and fires.

- Construction sites – Temporary supplies, tools, and site lighting must be RCD-protected to meet safety regulations.

- Medical areas – Sensitive RCDs (sometimes 10 mA) protect vulnerable patients and medical staff in critical zones.

RCDs are essential wherever there is a chance of electrocution or electrical fire. That could be in the home, workplace or outdoors. And, in many cases, installing an RCD isn't just good safety sense, it's a legal requirement.

RCD Compliance and Safety Regulations Worldwide

RCD requirements vary by country, but all aim to ensure protection against electric shock and fire. Here’s a quick run-through of some key standards and rules around the world:

- United Kingdom & Europe – Governed by IEC/EN 61008 and IEC/EN 61009 standards. The BS 7671 Wiring Regulations require 30 mA RCD protection for most socket-outlets, outdoor circuits, and certain fixed equipment.

- Australia & New Zealand – Covered by AS/NZS 3190 and AS/NZS 3000 (the Wiring Rules). 30 mA RCDs are mandatory for all socket circuits in residential and many commercial premises.

- United States – Known as GFCIs (Ground Fault Circuit Interrupters) under the NEC (NFPA 70). 5–6 mA trip threshold for personal protection in kitchens, bathrooms, garages, and outdoor outlets.

- Canada – Known as Class A GFCIs in the Canadian Electrical Code; similar 5 mA requirement for specified circuits in wet or outdoor locations.

- Japan – Uses ELCBs (Earth Leakage Circuit Breakers) per JIS C 8210. Common domestic rating is 30 mA, with lower trip currents in special facilities.

- International Standards – The IEC 60364 series provides the global framework for low-voltage installations, adopted in many regions with local amendments.

RCDs vs MCBs – What's the Difference?

Although both RCDs (Residual Current Devices) and MCBs (Miniature Circuit Breakers) are vital safety devices in modern electrical installations, they perform completely different protective roles.

- RCD (Residual Current Device)

The RCD’s job is to protect people from electric shock and to reduce the risk of fire caused by current leaking to earth. It constantly monitors the current flowing in the live and neutral conductors. If it detects an imbalance (meaning some current is “escaping” to earth), it trips almost instantly — usually within 30 milliseconds — to cut the power. - MCB (Miniature Circuit Breaker)

The MCB’s job is to protect the wiring and equipment from damage caused by excessive current. This can happen in two ways:- Overload – too much current drawn for too long (e.g., plugging too many appliances into one circuit).

- Short circuit – a sudden, very high current surge caused by a fault (e.g., live wire touching neutral).

MCBs have thermal and magnetic trip mechanisms that open the circuit when these conditions occur.

In most consumer units and distribution boards, RCDs and MCBs are used together so that both types of hazards are covered. In many cases, this is achieved by using RCBOs (Residual Current Breaker with Overcurrent Protection) — devices that combine both RCD and MCB functions in a single unit.

Comparison Table – RCD vs MCB vs RCBO

| Feature | RCD (Residual Current Device) | MCB (Miniature Circuit Breaker) | RCBO (Residual Current Breaker with Overcurrent Protection) |

|---|---|---|---|

| Primary Protection Purpose | Protects people from electric shock and reduces fire risk from earth leakage faults | Protects wiring and equipment from overcurrent damage | Combines both: protects people from electric shock and protects circuits from overcurrent |

| What It Detects | Imbalance between live and neutral currents (earth leakage) | Excessive current caused by overload or short circuit | Both earth leakage and overcurrent conditions |

| Trip Sensitivity | Very low, typically 30mA for personal protection; higher (100–300mA) for fire protection | Much higher, based on rated current (e.g., 6A, 16A, 32A) | Low for leakage (30mA typical) and high for overcurrent (MCB-rated) in the same unit |

| Trip Speed | Extremely fast – typically <30 milliseconds for personal protection | Fast, varies depending on overload or short circuit magnitude | Matches RCD speed for leakage and MCB speed for overcurrent |

| Protects Against | Electric shock from direct or indirect contact; fire from leakage currents | Overheating of cables and appliances; damage from short circuits | All of the above – shock, fire from leakage, overload, and short circuit damage |

| Does Not Protect Against | Overcurrent (overload or short circuit) | Earth leakage electric shock | None – covers both leakage and overcurrent |

| Reset Method | Manual reset after fault clearance | Manual reset after fault clearance | Manual reset after fault clearance |

| Common Installation Location | Consumer units, distribution boards (often protecting multiple MCB circuits) | Consumer units, protecting individual circuits | Consumer units, replacing separate RCD+MCB for individual circuits |

| Standards Compliance | BS EN 61008 (RCD) | BS EN 60898 | BS EN 61009 |

| Typical Brands from LED Controls | ABB RCDs, Chint RCDs | ABB MCBs, Chint MCBs | ABB RCBOs, Chint RCBOs |

| Best Used For | Life protection and fire prevention from leakage faults | Circuit and equipment protection from excess current | Full protection for individual circuits where space or simplicity is important |

| Works Without Earth? | Yes – detects imbalance, not earth presence (though earthing is still essential) | Yes – detects excess current regardless of earth connection | Yes – combines both detection methods |

Common Misconceptions About RCDs

- They protect against overcurrent – RCDs only protect against earth leakage currents, not overloads or short circuits (that’s the job of MCBs or fuses).

- They eliminate the risk of electric shock – They greatly reduce the risk, but can’t guarantee safety in all situations, especially with direct contact between live and neutral.

- One RCD can protect an entire installation without issues – A single RCD on a whole installation can lead to nuisance tripping and unnecessary power loss; multiple RCDs or RCBOs often work better.

- If it trips, the RCD must be faulty – Tripping is usually a sign of a wiring fault, appliance fault, or leakage, not a defective RCD.

- They don’t need regular testing – RCDs should be tested (with the built-in test button) at least every 3 months to ensure they still trip correctly.

Choosing the Right RCD from LED Controls

At LED Controls, we stock a full range of ABB and Chint RCDs in various types and ratings, all fully compliant with UK and international standards. Whether you're looking to safeguard your domestic wiring or keep employees and equipment running up to code in your workplace, our expert team can help you select the right device for safety, compliance, and reliability.

RCD FAQ

What is the difference between an RCD and RCCB?

An RCCB (Residual Current Circuit Breaker) is essentially the same as an RCD — both detect leakage current and trip when an imbalance is found. The term “RCCB” is often used in industrial contexts, while “RCD” is more common in domestic applications.

Why does my RCD keep tripping?

Likely causes include faulty appliances, moisture in wiring, damaged insulation, or shared neutral connections. Unplug everything and reset to identify the source, or call an electrician for testing.

What is the difference between Type A and B RCD?

Type A detects AC and pulsating DC currents, while Type B detects AC, pulsating DC, and smooth DC currents — making Type B suitable for EV chargers and certain industrial machinery.

How do I turn my RCD back on?

Locate the tripped RCD switch in your consumer unit, ensure the fault is cleared, and push the switch back to the ON position. If it immediately trips again, investigate the fault before retrying.

Do I need an RCD if I have an RCBO?

No. An RCBO combines the functions of both an RCD and an MCB, so separate RCD protection is not necessary on that circuit.

How to tell the difference between an RCD and RCBO?

RCBOs have markings for both residual current (mA) and overcurrent (A) ratings, while RCDs show only mA sensitivity.

Does RCCB trip on overload?

No. RCCBs only trip on earth leakage. Overload protection must be provided by an MCB or fuse.

What are the disadvantages of RCCB?

They cannot detect overcurrent, may trip due to nuisance faults, and if used for multiple circuits, a single fault can cut power to all.

What are the disadvantages of RCBO?

They are more expensive per circuit and take up more space in your consumer unit.

Can you mix RCD and RCBO?

Yes. It’s common to have some circuits protected by RCBOs and others under a main RCD.

How to tell if an RCD is faulty?

If pressing the test button doesn’t trip your RCD, or it trips erratically with no fault present, it may be faulty and require replacement.

How much does it cost to replace an RCD?

Typically £50–£150 including installation, depending on type, brand, and installation complexity.

Why is my RCD tripped for no reason?

There is always a reason, but often hidden. Common culprits include damp weather affecting outdoor wiring, minor appliance faults, or wiring issues.

Are type AC RCDs banned in the UK?

They are not banned but are being phased out in certain applications due to modern electrical loads that produce DC leakage.

Can you replace an RCD yourself?

Only a qualified electrician should replace RCDs, as it involves working inside the consumer unit.

Is it safe to switch RCD back on?

Yes, once you are certain the fault has been fixed. You must never repeatedly reset without finding the cause.

Can a toaster trip an RCD?

Yes. Toasters are a common source of leakage due to moisture or crumbs bridging live components to earth.

Troubleshooting Appliances That Trip Your RCD

If your RCD trips repeatedly when you use a certain appliance, it’s usually a sign of earth leakage: electricity finding an unintended path to earth through moisture, dirt, or faulty insulation. Follow these steps to help identify the culprit:

- Unplug All Appliances

Switch off the RCD and unplug everything on the affected circuit. Reset the RCD. If it now stays on, the problem is with something you unplugged. - Reconnect One by One

Plug in and switch on each appliance in turn. The one that causes the RCD to trip is your likely suspect. - Check the Common Offenders

- Ovens & Cookers: Grease and food residue on heating elements can carbonise and cause leakage. Moisture from spills or cleaning can also cause tripping.

- Kettles & Coffee Machines: Limescale buildup or water leaks can allow current leakage to earth.

- Washing Machines & Dishwashers: Heating elements, pumps, or moisture ingress in control panels are common culprits.

- Fridges & Freezers: Defrost heaters and damp insulation can trigger leakage, especially in older units.

- Outdoor Equipment: Lawn mowers, pressure washers, and extension leads can suffer from water ingress.

- Look for Patterns

If the RCD only trips when the appliance is heating up, the issue is likely with a heating element. If it trips immediately when switching on, it could be internal wiring or the motor. - Avoid Repeated Resetting

Repeatedly switching the RCD back on without fixing the fault can be dangerous — it’s there to protect you. If in doubt, stop and call a qualified electrician.

Many faults that cause RCD tripping are intermittent and temperature-dependent. A fault may not appear during a quick test but could show up once the appliance heats up or after moisture has built up inside.

How to Test an RCD – Step-by-Step

Regularly testing your RCD is important to make sure it will work when you need it. Most manufacturers recommend doing this every 3 months. Here’s how:

- Find your RCD

Locate the device in your consumer unit (fuse box) or distribution board. It will usually have a small button marked “T” or “Test”. - Warn anyone using electrical equipment

Testing will cut the power to the circuits the RCD protects. Let others know so they can save work or pause appliances. - Press the Test button

Use your finger to press the “Test” button firmly. This creates a small fault current to simulate a leakage to earth. - Check it trips instantly

The RCD switch should flip to the “off” position immediately. This shows it has detected the fault current and disconnected the supply. - Reset the RCD

Return the RCD to the “on” position by pushing the switch back up. Power should be restored to the protected circuits. - If it doesn’t trip

If pressing the button does nothing, the RCD may be faulty. Turn off the main power and contact a qualified electrician to inspect or replace it.

Some manufacturers, such as ABB, provide RCDs with automatic testing features that won't even break your workflow. Find out more here.

LED Controls - your Expert RCD Dealer

If you are looking to upgrade your RCDs, place your next order, are new to the electronics market or just still have questions about RCDs, just get in touch with LED Controls. RCDs are a key component in electronic panels both domestic and industrial, and we are proud to be a trusted provider of these essential bits of safety-conscious kit.

01706 242050

[email protected]

www.ledcontrols.co.uk