We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Keep On Top of your Maintenance, Repair and Operations (MRO) with LED Controls and Danfoss DrivePro®

In Industry and Electrical, MRO stands for Maintenance, Repair and Operations (or sometimes Overhaul). This covers routine checks, scheduled replacement of worn parts, urgent repairs, and the supply of tools and equipment needed for these jobs. It also covers items that support operations but are not part of the finished product, such as safety gear, spares, lubricants and electrical components.

In a factory or complex building, good MRO helps machinery continue to run without costly downtime and ensures systems like lighting, ventilation, heating and controls are safe, compliant and efficient. It often includes preventive and predictive maintenance, where technicians look for signs of wear before a fault becomes a breakdown.

Maintenance

Maintenance is the general upkeep of equipment, with the intention of preventing problems before they arise. This includes regular inspections, testing and servicing. In electrical automation, maintenance might involve checking connections, cleaning panels, updating firmware, testing backups, and verifying that systems are operating within intended parameters.

Good maintenance reduces wear and tear, and helps your equipment last longer. It also makes faults easier to spot early, when they are cheaper and quicker to fix. Planned maintenance is usually far less disruptive than dealing with an unexpected failure, so maintenance helps reduce the need for repair.

Repair

Repair - obviously - is the process of fixing things when they go wrong. This can range from replacing a failed component - such as a power supply or drive - to restoring a PLC programme after hardware failure. Repairs are often time-critical, especially in production environments where any shutdown costs you money.

Effective repair work depends heavily on preparation. Having the right spare parts available, clear documentation, and backed-up configurations makes repairs faster and reduces the risk of repeat failures. While repairs are sometimes unavoidable, strong maintenance practices can reduce how often they are needed.

Operations

In MRO, Operations refers to the planning and preparation needed to enable your maintenance and repair procedures to run as smoothly as possible.

This could mean managing spare parts and stock levels, keeping documentation up to date, supporting system changes, ensuring equipment is used correctly, or all of the above. In automation and controls, operations also includes managing energy use, monitoring system performance, and supporting upgrades or improvements over time. This is where "Overhaul" becomes applicable, as Operations may include scheduled upgrades/refurbishments/replacements in order to avoid breakdown.

Without good operational planning, you won't be on top of your maintenance, and your repairs will become reactive and disorganised, which could ultimately mean longer unplanned downtime at greater cost to you. Solid operations ensure that your people, parts and processes are aligned to support the site as a whole.

What happens when you neglect your MRO?

More breakdowns and unplanned downtime

Running equipment until it fails leads to sudden, unexpected stoppages. Unplanned downtime is usually more expensive than scheduled maintenance and often takes longer to resolve. It can also disrupt staff, suppliers and customers.

Inefficient and overworked components

Old or poorly maintained components often work harder than they should. This increases wear and tear and causes systems to draw more electrical power, which can significantly increase your energy consumption and operating costs over time.

Shorter equipment lifespan

When faults are left unresolved, components degrade faster. Equipment that should last many years may need replacing early, increasing capital spending and disrupting long-term planning.

Hidden operational costs

Frequent failures can affect product quality, safety and compliance. Emergency repairs often require overtime labour or rush-ordered parts, both of which cost more than planned maintenance work.

LED Controls: Your Complete MRO Partner

LED Controls aims to help customers move from reactive fixes to structured, long-term MRO programmes. We supply critical components you need to keep your site running, including variable speed drives, PLCs, motor control and protection devices, sensors and connectors. Fast procurement and flexible delivery options, including next-day and selected same-day delivery, ensure your emergencies are resolved quickly and maintenance work stays on schedule.

For ongoing support, our on-site consignment stock options keep your essential spares available without tying up capital, while our bespoke kitting service simplifies maintenance and panel updates. This is backed by experienced technical support and dedicated account management, giving customers practical guidance and a more predictable, well-managed MRO programme.

Bringing Danfoss MRO services directly to your site

As a Danfoss Drives Authorised Partner, LED Controls can bring the full range of Danfoss DrivePro® Maintenance, Repair and Operations services directly to customers. These services support drive systems across their entire lifecycle, helping improve reliability, reduce downtime and extend asset life as part of a structured MRO programme.

Danfoss DrivePro Services:

DrivePro® Site Assessment

A structured review of your installed drives to assess condition, criticality and risk. This provides a clear starting point for maintenance planning, obsolescence management and lifecycle decisions.

DrivePro® Start-up

Expert commissioning to ensure drives are installed, configured and fine-tuned correctly from day one. This reduces early failures, improves energy efficiency and sets the foundation for reliable long-term operation.

DrivePro® Extended Warranty

Extended cover beyond the standard warranty period, helping control maintenance costs and reduce financial risk while maintaining access to approved service expertise.

DrivePro® Spare Parts

Access to approved Danfoss spare parts to support fast, reliable repairs and reduce downtime caused by unavailable or incorrect components.

DrivePro® Preventive Maintenance

Planned, condition-aware maintenance tailored to operating environment, load and running hours. This reduces unplanned breakdowns and extends the working life of drive systems.

DrivePro® Exchange

A rapid replacement service that minimises downtime by providing pre-tested replacement drives when a failure occurs.

DrivePro® Retrofit

A controlled upgrade path for ageing or obsolete drives, allowing improved performance, efficiency and reliability without the disruption of a full system replacement.

DrivePro® Remote Monitoring

Ongoing monitoring of drive performance and operating conditions to identify early warning signs and support proactive maintenance decisions.

Danfoss Drives Condition-Based Monitoring

Danfoss drives also support Condition-Based Monitoring, which continuously tracks operating conditions for early signs of wear or abnormal behaviour, making sure your maintenance team can take targeted maintenance action.

So LED Controls and Danfoss DrivePro® services form a complete, lifecycle-based MRO framework tailored to your specific needs.

MRO planning Tailored to your Requirements

If you're ready to upgrade your automation, HVAC or industrial controls MRO programme, LED Controls can arrange for a member of our team and a Danfoss representative to visit your site and asses your needs directly. We can survey your current systems and deliver efficiency payback reports, obsolescence plans and energy-management strategies specifically for your systems.

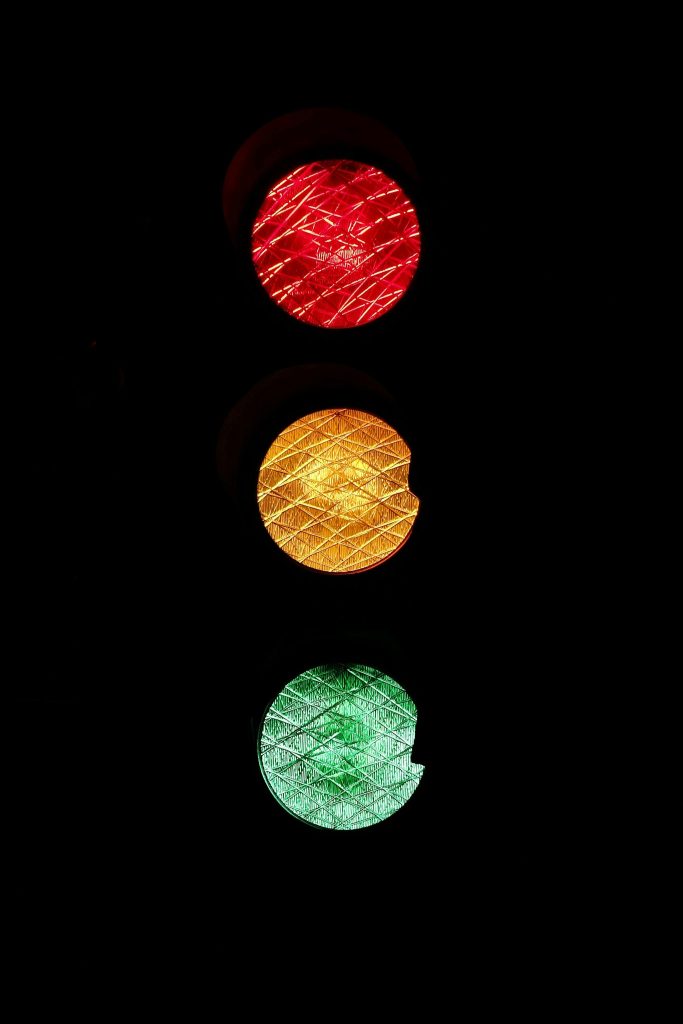

Green Means Go

Using a traffic light method, we can advise on the best course of action for every part of your system:

- RED - A component requires immediate replacement or repair.

- ORANGE - A component requires an obsolescence plan. If you want your system to keep running uninterrupted, now's the time to take measures in anticipation of the end of this part's lifetime.

- GREEN - This component is optimised and capable, still well within its lifespan, and will continue to give good results at least until your next MRO survey.

LED Controls have access to the right parts and expertise to help you tackle both routine maintenance and urgent repairs. Whether it is replacing a worn-out drive, updating a PLC, managing stocks of connectors and safety parts, or bringing in the Danfoss big guns to future-proof your entire MRO plan, LED Controls can help keep your facilities running reliably.

Get in touch to find out how we can help you:

01706 242050

[email protected]

ledcontrols.co.uk