We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Danfoss FC 102: The HVAC Engineer's Drive

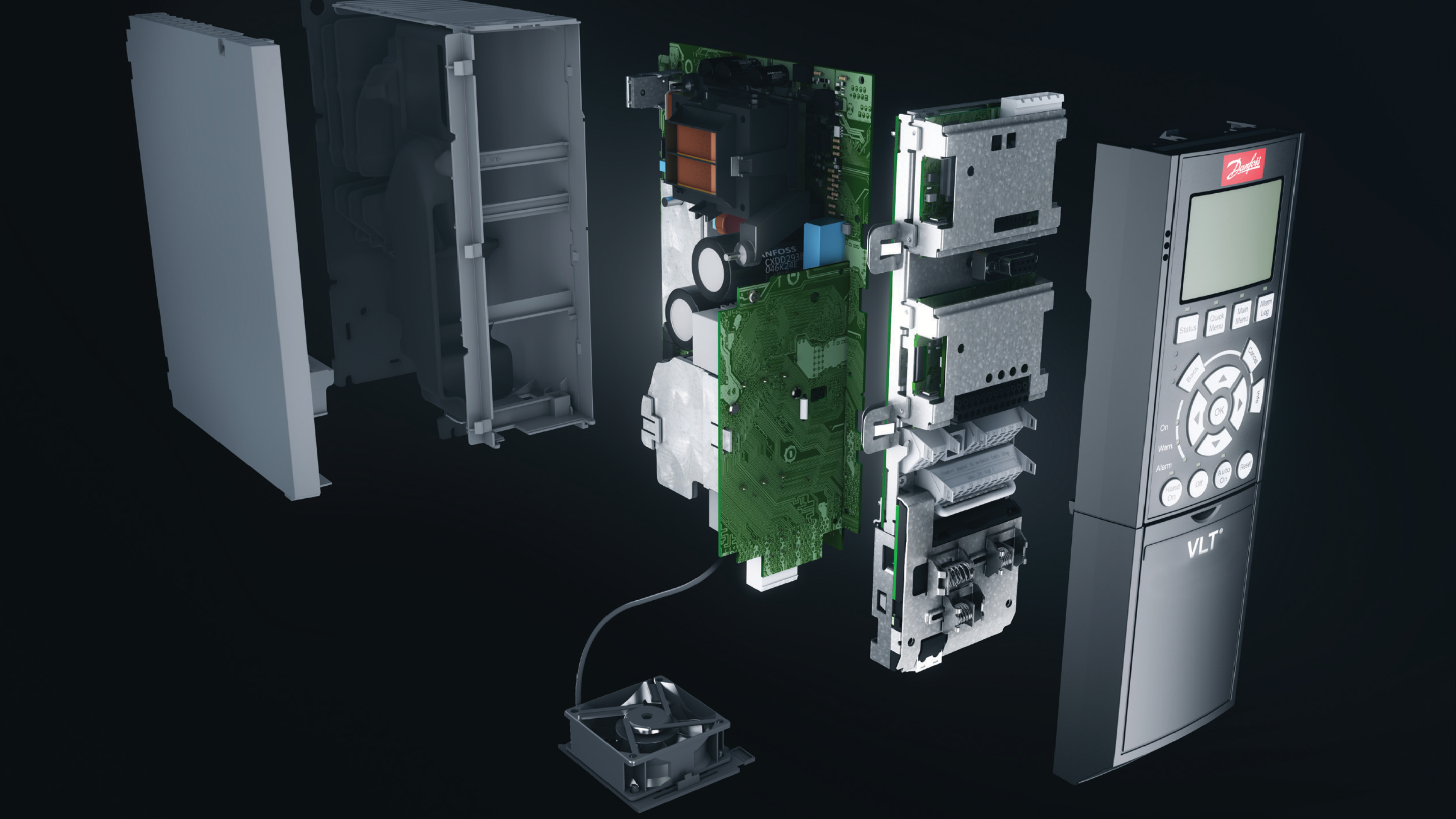

The Danfoss FC 102 (VLT® HVAC Drive) is one of the most widely used variable speed drives in building services. Designed specifically for HVAC, it provides accurate speed control for fans, pumps and compressors, improving efficiency and comfort while reducing running costs. If you're in the HVAC business, you should be in the Danfoss FC102 business!

What is HVAC?

HVAC stands for Heating, Ventilation and Air Conditioning. Systems that keep indoor environments comfortable, healthy and energy efficient. Heating maintains a safe and pleasant temperature in cooler weather, ventilation brings in fresh outdoor air and removes stale or contaminated air, and air conditioning provides cooling and humidity control during warmer periods. These systems combine to manage temperature, airflow, moisture and air quality across buildings such as offices, schools, hospitals and industrial sites. For engineers, HVAC is all about delivering the right conditions for people and processes while using energy as efficiently as possible.

What the Danfoss FC 102 does in HVAC systems

The FC 102 continuously adjusts motor speed to match the demand of the system. So instead of a fan or pump running at full speed all the time, the drive slows or speeds the motor based on building load. This is ideal for:

- Supply and extract fans

- Chilled and heating water pumps

- Rooftop units and AHUs

- Compressors in chillers and heat pumps

Find out more about Variable Speed Drives in general in our helpful guide: What is a Variable Speed Drive?

Key benefits for HVAC engineers

Energy efficiency and reduced operating costs

HVAC motors rarely need to run at full output. Reducing motor speed even slightly delivers major energy savings due to the cubic relationship between speed and power. So FC 102 drives can help deliver:

- 30–40 percent savings on compressors

- 50–70 percent savings on pumps and fans

This makes the drive a strong asset for achieving energy-efficient designs, BREEAM targets and carbon reduction plans.

Improved comfort and air quality

Because Danfoss FC 102 ramps up smoothly, it avoids the sudden blasts of air that come with fixed-speed or stepped systems. Benefits include:

- Stable room temperatures

- More consistent duct pressure

- Reduced noise

- Finer control in sensitive areas such as healthcare, cleanrooms and laboratories

Built-in HVAC intelligence

The FC 102 includes a wide set of HVAC-specific functions designed to make setup easier, reduce the need for external controls and improve overall system performance. These features are built into the drive firmware, so you can apply them without programming a PLC or adding extra hardware.

Sleep mode and auto-restart

Sleep mode automatically stops the motor when demand is low enough that continued operation is unnecessary, such as during night-time cooling or periods of low water flow. The drive monitors system pressure or flow and restarts the motor when conditions rise again.

Why it matters: It prevents the system running at low load where efficiency drops.

Benefits: Lower energy consumption, reduced wear on motors and quieter operation during low-demand periods.

Filter monitoring with pressure sensors

The FC 102 can read differential pressure signals from filters in AHUs or ventilation systems. As the filter becomes clogged, the pressure drop increases. The drive detects this and can generate warnings or alarms.

Why it matters: Blocked filters reduce airflow, cause fans to work harder and increase energy use.

Benefits: Predictive maintenance, better indoor air quality and reduced energy waste from overworked fans.

Pump and fan cascades

Cascade control allows the drive to manage multiple pumps or fans working together. It can bring additional units online as demand rises and switch them off when demand falls. The FC 102 automatically rotates lead and lag equipment to balance wear.

Why it matters: Large HVAC systems often require multiple units to meet varying loads throughout the day.

Benefits: Longer equipment life, balanced hours across pumps or fans and smoother control without sudden pressure spikes.

Fire Emergency Mode

In the event of a fire, some HVAC systems need to keep running to maintain smoke control or pressurise escape routes. Fire mode allows the drive to override standard protections and run continuously under emergency conditions.

Why it matters: Standard drives would trip on overload or temperature faults during extreme events.

Benefits: Compliance with safety standards, dependable smoke management and improved evacuation conditions.

Condition-based monitoring

Condition-based monitoring (CBM) uses built-in diagnostics to track vibration, motor temperature, load patterns and early signs of mechanical problems.

Why it matters: Unexpected fan or pump faults can cause major disruption to building comfort and critical processes.

Benefits: Early fault detection, reduced unplanned downtime and more efficient maintenance scheduling.

Easy integration with Building Management Systems (BMS)

The drive supports Modbus, BACnet and other building-management protocols via option cards. This makes it easy to pass alarms, status information and energy data to the BMS without extra gateways.

Suitable for demanding HVAC environments

The FC 102 comes in multiple enclosure ratings including IP20, IP21, IP54, IP55 and IP66. Higher-rated versions withstand dust, humidity and direct mounting in hot plant rooms. Some drives can operate up to 50 °C without derating. Find out more about IP Ratings here.

Comparison table of FC 102 variants

| Variant family | Voltage and phase | Typical power range | IP rating(s) | Common HVAC uses |

|---|---|---|---|---|

| FC 102, 1 × 200–240 V | Single-phase 200–240 V | 1.1–22 kW | IP20 / IP21 | Small AHUs, fan coils, small pumps |

| FC 102, 1 × 380–480 V | Single-phase 380–480 V | 7.5–37 kW | IP20 / IP21 | Niche retrofit applications |

| FC 102, 3 × 200–240 V | Three-phase 200–240 V | 1.1–45 kW | IP20 / IP21 | Packaged plant, small AHUs, low-voltage networks |

| FC 102, 3 × 380–480 V, IP20 | Three-phase 380–480 V | 1.1–160 kW | IP20 | Standard fans, pumps and compressors |

| FC 102, 3 × 380–480 V, IP54/IP55 | Three-phase 380–480 V | 11–355+ kW | IP54 / IP55 | Large AHUs, cooling towers, big pumps |

| FC 102, 3 × 525–600 V | Three-phase 525–600 V | 1.1–90 kW | IP20 / IP21 | Industrial HVAC, infrastructure cooling |

| FC 102, 3 × 525–690 V | Three-phase 525–690 V | Up to 1400 kW | IP20 / IP21 / IP55 (depending on configuration) | District cooling, tunnel ventilation |

Practical selection guidance

When selecting an FC 102 for your HVAC project, consider:

- Supply voltage and phase

Ensure the variant matches the electrical network. - Motor power and current

Select a unit that matches or slightly exceeds full-load current. - Enclosure rating

Choose IP20/IP21 for panels, IP54/IP55/IP66 for wall-mounting near plant. - BMS protocol requirements

Select Modbus, BACnet or relevant options early in the design. - Harmonic requirements

Use low-harmonic models or appropriate filters where needed. - Application-specific functions

Take advantage of fire mode, filter monitoring and automatic energy optimisation.

Buying FC 102 drives from LED Controls

If you're after a reliable, energy-efficient drive solution for your HVAC system, the Danfoss FC 102 offers excellent performance, strong manufacturer support and a broad range of options to suit almost any building. Check out LED Controls' range here.

Or get in touch to discuss your requirements with our expert team:

01706 242050

[email protected]

ledcontrols.co.uk