We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Automatic Transfer Switching (ATS) with Lovato GLCM and ATL

Automatic Transfer Switch (ATS) systems automatically transfer electrical load from the mains supply to a backup generator when a failure is detected. At LED Controls, we utilise Lovato GLCM motorised changeover switches and LOVATO ATL automatic transfer controllers for a reliable, intelligent and fully automatic power transfer system.

How does an Automatic Transfer Switch System Work?

- The controller monitors incoming power

- If the mains fails, the generator starts

- The load transfers automatically

- When mains power returns, the system switches back

This entire process happens without manual intervention, keeping your systems running smoothly even if there's a fault when unsupervised.

Lovato GLCM Motorised Changeover Switches

Lovato GLCM motorised changeover switches provide the switching mechanism within an ATS system. They physically transfer the load between two power sources. Unlike manual changeover switches, which require a person to flick the switch, Lovato GLCM switches operate automatically using a motor drive mechanism. This ensures fast, safe and repeatable switching, and means you can go on your tea break without worrying about electrical faults.

Key features of the GLCM range

- Three-pole and four-pole configurations

- Current ratings typically from 125A to 315A

- Control voltage options including 24V DC, 110V AC/DC and 230V AC

- Mechanical interlocking to prevent both power sources connecting at the same time

Mechanical interlocking is critical in generator systems. It guarantees that mains and generator supplies can never be connected simultaneously, protecting equipment and ensuring safe operation.

LOVATO ATL Automatic Transfer Controllers

If Lovato GLCM is the switching mechanism, LOVATO ATL is the intelligence behind the system. These controllers continuously monitor voltage and frequency on both mains and generator supplies. When abnormal conditions are detected, they manage the full transfer sequence.

LED Controls supplies the complete LOVATO ATL range:

ATL100

The LOVATO ATL100 is designed for basic two-source power systems. It provides reliable mains-to-generator switching with a simple control interface, making it a cost-effective choice for small commercial and light industrial installations.

ATL500

The LOVATO ATL500 is a compact automatic transfer controller with built-in NFC for quick wireless setup. Ideal for straightforward generator applications requiring simple, reliable automatic transfer control.

ATL600

The LOVATO ATL600 features an integrated LCD display and optical port for clear system visibility and easy configuration. Well suited to commercial and industrial installations needing on-board monitoring.

ATL601

The LOVATO ATL601 is equipped with an optical port for easy communication and configuration on a 12–24 V DC auxiliary supply. It is designed for two-source power systems and works well in installations where reliable status feedback and straightforward control are needed.

ATL610

The LOVATO ATL610 is a compact and cost effective controller ideal for standard generator installations. It provides reliable automatic transfer without unnecessary complexity.

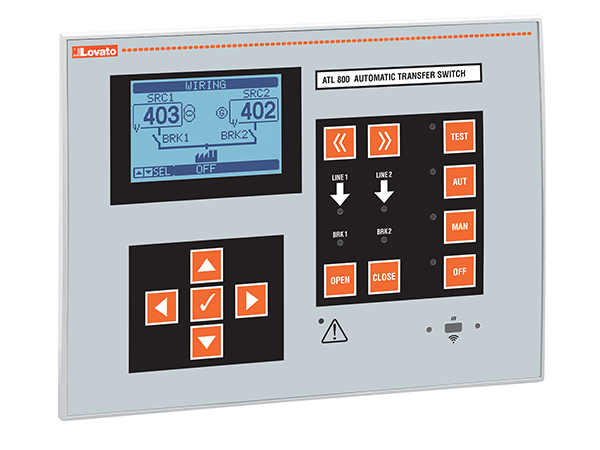

ATL800

The LOVATO ATL800 offers enhanced monitoring, configurable parameters and improved system visibility. It is well suited to commercial buildings and industrial facilities.

ATL900

The LOVATO ATL900 is a high performance programmable controller designed for complex and critical systems. It is commonly used in data centres, healthcare facilities and infrastructure projects where uptime is essential.

How Lovato GLCM and LOVATO ATL Work Together

Imagine a system with two possible sources of electricity:

- The mains supply from the grid

- An on-site backup generator on site

If the mains power fails, the system needs to automatically switch to generator power. When the mains comes back online, the system should safely switch back again. Here is how that happens:

Step 1: The LOVATO ATL Controller Monitors the Incoming Power

The ATL controller is permanently connected to the incoming mains supply. Its job is to measure the electrical conditions at all times:

- Voltage, which is the pressure of the electricity

- Frequency, which relates to the stability of the power

- Whether all phases are present in a three phase system

This monitoring happens continuously, many times per second. The controller is not switching anything at this stage. It is simply watching and measuring and - as long as the voltage and frequency remain within safe preset limits - nothing changes. The building continues running on mains power.

Step 2: The ATL Controller Detects a Problem

If something goes wrong, for example:

- A full power cut

- Voltage drops too low

- One phase fails in a three phase system

The LOVATO ATL detects that the electrical supply is outside its safe operating limits. The controller does not react instantly. It waits for a short, programmed delay to prevent momentary power fluctuations from causing unnecessary generator starts. If the fault continues beyond this delay, the controller confirms that the mains supply is genuinely unavailable or unsafe.

Step 3: The Generator Is Started

Once the controller confirms a real mains failure, it sends a start signal to the backup generator. The generator begins producing electricity, but at this stage it is not yet connected to the system. The system now has two separate electrical sources:

- The failed or unstable mains supply - still connected

- The generator that is warming up and building stable output - not connected yet

Step 4: The Controller Waits for Stable Generator Power

A generator may need a moment to reach speed and produce stable voltage and frequency. The LOVATO ATL controller measures the generator output to check:

- The voltage is within the safe range

- The frequency is correct

- All phases are present and balanced

Only when the generator output is stable does the controller move to the next step. This prevents damaged equipment and ensures that sensitive loads are not connected to unstable power.

Step 5: The Lovato GLCM Motorised Changeover Switch Transfers the Load

Now the controller sends a command to the Lovato GLCM motorised changeover switch. Inside the GLCM unit is a motor mechanism that physically moves the internal contacts from one position to another:

- First, it disconnects the building from the mains supply

- It moves through a neutral OFF position

- Then it connects the building to the generator supply

The switch is mechanically interlocked. This means it is physically impossible for both power sources to be connected at the same time. This is extremely important to help protect workers and the equipment itself.

At this point, the system is running entirely on generator power.

Step 6: The System Continues to Monitor Both Supplies

The LOVATO ATL controller continues to monitor both generator output and mains supply, ensuring that the generator is running as normal and checking for indications that the mains is regaining stability

Step 7: Mains Power Returns

When the mains supply comes back, it may not be immediately stable. Voltage can fluctuate briefly during restoration. The LOVATO ATL controller again waits for a programmed delay period to ensure the mains supply has fully stabilised before any switching takes place. Only when voltage, frequency and phase conditions are nominal does the controller initiate the return sequence.

Step 8: The Load Is Transferred Back to Mains

The LOVATO ATL controller sends another operation instruction to the GLCM motorised changeover switch, activating the reverse sequence:

- It disconnects the system from the generator

- Passes through the OFF position

- Reconnects the system to the mains supply

Again, mechanical interlocking ensures the two sources are never connected together. Once the load is safely back on mains power, the controller sends a stop signal to the generator.

Step 9: The Generator Shuts Down Safely

The generator may continue running briefly for a cool down period. This protects the engine from thermal stress. After the cool down delay, the generator stops and returns to standby mode. The system is now back in its original condition, ready to respond to the next power interruption.

Why This Process Matters

This carefully controlled sequence provides:

- Fast and safe automatic transfer

- Minimal disruption to operations

- Protection for sensitive equipment

- Elimination of manual switching errors

- Safe isolation between power sources

Because Lovato GLCM motorised changeover switches are built using the same robust engineering principles as Lovato Switch Disconnectors, they provide reliable isolation and long service life in demanding environments.

The LOVATO ATL controller collects information and makes decisions based on your pre-set parameters. The Lovato GLCM switch takes physical action. Together, they create a complete and intelligent automatic transfer system that protects both people and equipment.

Applications for Lovato GLCM and LOVATO ATL Systems

Lovato GLCM motorised changeover switches and LOVATO ATL controllers are widely used in:

- Manufacturing plants

- Warehousing and logistics centres

- Commercial buildings

- Hospitals and healthcare sites

- Data centres

- Water treatment facilities

- Agricultural and rural installations

If you're running a site with a standby generator, you can exponenentially improve reliability and safety by installing a Lovato GLCM and LOVATO ATL automatic transfer system.

Why Buy Lovato GLCM and LOVATO ATL from LED Controls

When you purchase Lovato GLCM motorised changeover switches and LOVATO ATL automatic transfer controllers from us, you benefit from:

- Competitive UK pricing

- Expert product guidance

- Fast and reliable delivery

- Support with specification and selection

So when you need a complete ATS solution, make sure you combine GLCM with ATL, and LED Controls with Lovato Electric! For more details, get in touch.