We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

ABB Overloads: Thermal vs Electronic Protection Explained

ABB Overloads protect motors against overheating, phase loss and sustained overcurrent. They form a vital part of any motor starter and help prevent costly downtime or damage. At LED Controls, we supply a full range of ABB Overloads, including both thermal and electronic varieties. Understanding the differences will help you pick the ideal bit of kit for your job.

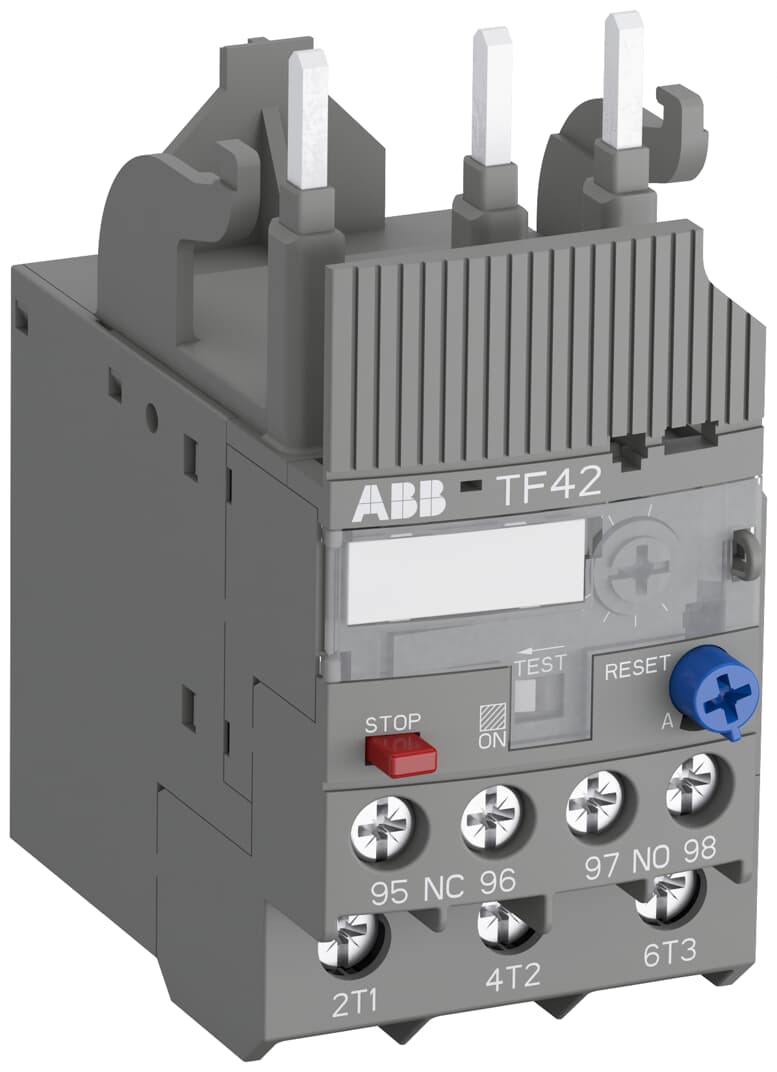

What Thermal Overload Relays Do

Thermal overload relays are electromechanical devices that use a bimetallic strip to sense heat generated by motor current. When a motor draws too much current for too long, the strip bends and triggers a trip, which cuts power to the motor and prevents overheating.

Where Thermal Overloads Are Used

Thermal overloads are ideal for stable, predictable loads such as pumps, fans, conveyors and small industrial machinery. Because they allow a time delay, they handle typical motor inrush without nuisance tripping.

Benefits of Thermal Overloads

• Cost-effective protection for everyday applications

• Simple installation and setup

• Adjustable current range to suit the motor

• Can be paired easily with ABB contactors for compact starters

Read more about how ABB Contactors work with Overload Relays HERE.

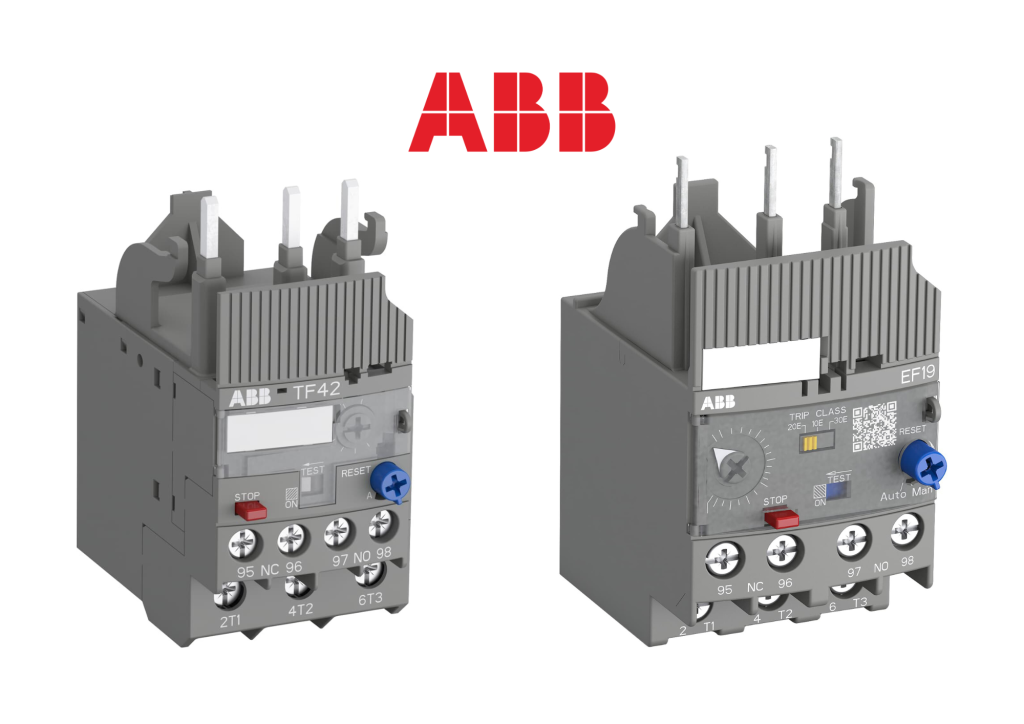

What Electronic Overload Relays Do

Electronic overload relays use sensors and electronic processing to monitor motor current accurately. They are not affected by ambient temperature and can provide faster, more precise protection. Some models also detect phase imbalance and locked-rotor conditions, offering a wider protection profile.

Where Electronic Overloads Are Used

Electronic overloads suit larger motors, variable loads and critical systems where fast fault detection prevents expensive downtime. They are common in production machinery, compressors, pumping stations and automated equipment.

Benefits of Electronic Overloads

• High accuracy and consistent performance

• Immune to ambient temperature changes

• Advanced protection functions for demanding applications

• Better suited to fluctuating or heavy start-up loads

Comparison and Recommendation Table

| Feature / Attribute | Thermal ABB Overloads | Electronic ABB Overloads (EF-Series) |

|---|---|---|

| Typical current-setting range | Covers very small motors from around 0.1 A up to roughly 100 A, depending on the series. | Extremely wide coverage, from below 1 A for compact motors right up to units protecting over 800 A. |

| Number of poles supported | Standard three-pole protection for three-phase motors, with auxiliary contacts for signalling. | Three-pole protection with electronic sensing and auxiliary outputs for control and monitoring. |

| Trip behaviour | Electromechanical using a bimetal strip, providing a natural time delay suited to motor start-up. | Electronic sensing provides faster, more accurate trips with consistent behaviour regardless of ambient temperature. |

| Stability in varying environments | Can be affected by ambient temperature, altering trip sensitivity. | Temperature-independent performance, ideal for fluctuating or demanding environments. |

| Suitable applications | Pumps, fans, conveyors and general-purpose three-phase motors. | Larger or more critical motors, variable loads, automation systems and continuous-duty equipment. |

Which ABB Overload Should You Choose?

If your motor runs with a steady load and cost efficiency is the priority, a thermal overload is often the best fit. It gives dependable protection and is straightforward to install.

If the application is critical, the load varies or the motor is part of a larger automated system, an electronic overload offers the precision and responsiveness you need.

If you have any further questions, get in touch with the ABB experts at LED Controls here.

Thermal vs Electronic ABB Overloads: Frequently Asked Questions

What is the main difference between thermal and electronic ABB Overloads?

Thermal overloads use a heated bimetal strip that bends and trips when the motor draws too much current for too long. Electronic overloads use sensors and digital processing to detect overloads more accurately and without being affected by ambient temperature.

Which type of ABB Overload is best for small motors?

For small or steady-load motors, thermal overloads are usually the most cost-effective choice. They provide dependable protection and are simple to install. You can browse options here:

ABB Thermal Overloads

When should I choose an electronic ABB Overload instead of a thermal one?

Electronic overloads are ideal for larger motors, variable loads or critical machinery. Their faster and more precise detection helps prevent damage in demanding environments. View the EF-Series here:

ABB EF Electronic Overloads

Do both types of overload relay protect against short circuits?

No. Neither thermal nor electronic overload relays provide short-circuit protection. They must be used alongside fuses or circuit breakers to give full motor protection.

Are thermal overloads affected by temperature?

Yes. Because the bimetal strip responds to heat, high or low ambient temperatures can slightly alter trip accuracy. Electronic overloads do not have this issue.

Do ABB Overloads work with ABB contactors?

Yes. Both thermal and electronic ABB Overloads are designed to pair cleanly with ABB contactors to form compact, reliable motor starters. This makes them easy to integrate into new or existing control panels.

What current ratings do ABB Overloads cover?

Thermal overloads typically cover ranges from about 0.1 A up to around 100 A. Electronic EF-Series overloads span a much wider range, from below 1 A up to more than 800 A, depending on the model.

Can an overload relay reset automatically?

Many ABB Overloads offer both manual and automatic reset options. Automatic reset can reduce downtime, while manual reset ensures the motor is checked before restarting.

Are electronic overloads harder to set up?

Electronic overloads may involve slightly more configuration, but most models are straightforward once installed. Their accuracy and advanced features often make them worth the extra flexibility.