We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

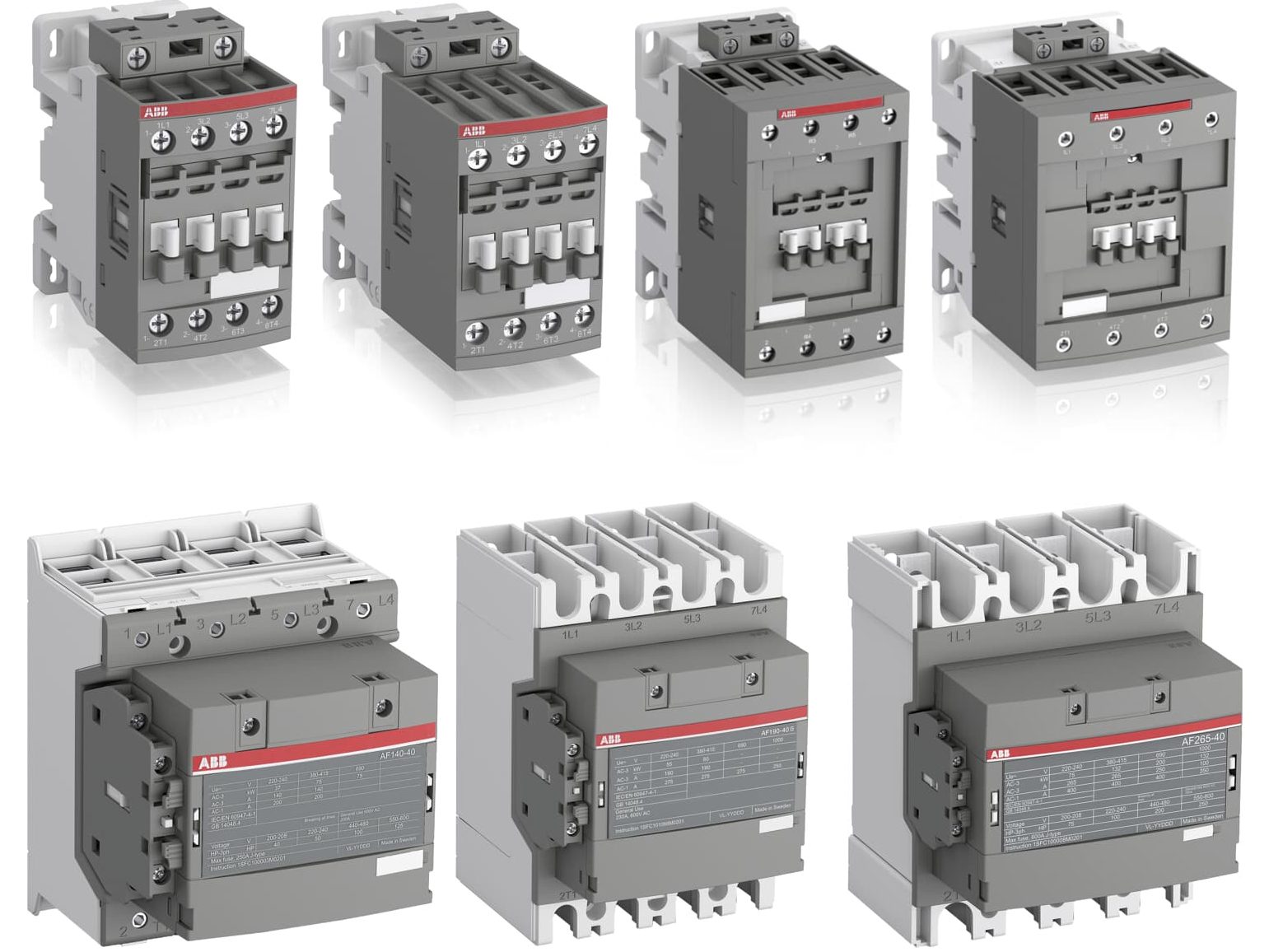

ABB AF Contactors and Overload Relays - The LED Controls Guide

Electric motors keep most industrial and commercial processes moving. If your business is running pumps, fans, compressors or conveyors, you're going to want a dependable way to switch motors and protect them from overload. This is why you combine AF Contactors and overload relays from ABB for a complete motor starter system that is simple to specify, straightforward to install and trusted across the world.

What do ABB AF Contactors do?

A contactor is a power switch controlled by a low voltage coil. It uses that coil to open or close robust contacts that carry the motor current. This lets you switch motors using a small control signal, often from a panel switch or PLC output.

The ABB AF range stands out because it replaces the old style magnet coil with an electronic coil. This accepts a very wide voltage range, works with AC or DC, filters out dips and spikes and includes built in suppression. In practice this means fewer coil variants to stock, less noise, improved reliability and easier installation.

3-pole or 4-pole contactors?

Most motor-control applications use 3-pole contactors, because three-phase motors only need three live conductors switching together. A 3-pole device is therefore the standard choice for motor starting, pump control, HVAC drives and general industrial machinery. It offers everything required for switching three-phase power neatly and reliably.

A 4-pole contactor includes an additional switching pole. That extra pole can be used in several useful ways, depending on the installation. It is often employed to switch a neutral conductor in lighting and heating circuits, or to provide full isolation where four conductors must be broken together. It can also help with load configurations where all poles need to be positively opened for safety or functional reasons.

So a 3-pole contactor will do for almost all motor duties, while a 4-pole contactor is called for when you need to switch an extra conductor or when the load demands all poles to operate in unison.

What do ABB overload relays do?

An overload relay is placed in series with the motor to monitor its current. If the current rises above the safe level for too long, the relay trips. This stops the motor before it overheats or fails. ABB offers two main Overload families:

Thermal (TF series)

The TF Series uses a bimetal strip that warms when current flows. They are simple, dependable and ideal for general duty. An example is the TF42 thermal overload or, for larger installations try the TF96 range.

Electronic (EF series)

The EF Series uses electronic current sensing for higher accuracy. They provide adjustable trip classes and phase loss protection and are well suited to critical motors. Examples include the EF45-30 electronic overload relay for 9 to 30 A, and the higher range EF45-45 model for 15 to 45 A.

Trip class selector explained

The EF series Trip Class selector allows you to choose how quickly the relay responds to an overload, matching the behaviour of the protection to the type of motor and the load it drives.

- Class 10E

A fast response suited to light-to-medium duty motors that should not tolerate extended overloads. Ideal for applications where rapid protection is essential. - Class 20E

A balanced middle option that allows a slightly longer delay, helping prevent nuisance trips on equipment that experiences short, harmless periods of higher load. - Class 30E

A slower trip class designed for high-inertia machinery or loads that naturally produce longer start-up currents. Suitable for large fans, heavy conveyors or machines with long acceleration times.

By selecting the right trip class, you ensure the relay reacts appropriately to real faults without interrupting normal operation. This flexibility is one of the main reasons panel builders choose the EF series over fixed-timing thermal relays.

How ABB AF Contactors and Overloads work together

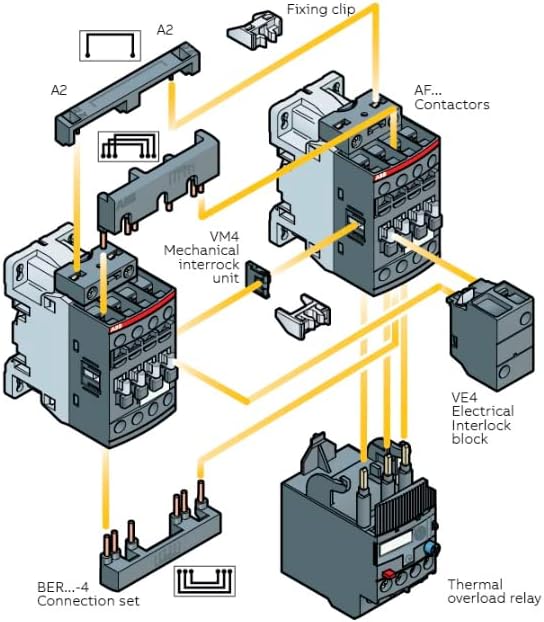

AF contactors and TF and EF overload relays are designed to fit together neatly. The overload relay mounts underneath the contactor and is wired in series with the motor. If it detects an overload, it automatically drops the control circuit to the contactor coil. The contactor opens, isolating the motor.

This arrangement is known as a Direct On Line (DOL) starter. It is widely used because it is compact, simple and reliable, combining everything you need in one tidy stack.

Choosing the right pairing

- Check the motor nameplate for kW rating and FLC.

- Select an ABB AF Contactor suitable for your motor’s kW. For example, AF09 suits small motors up to about 4 kW, while AF116 suits motors around 55 kW.

- Choose a matching ABB overload relay whose adjustable range covers the nameplate FLC. TF relays suit general duty while EF relays suit higher value machinery.

- Check whether the system requires manual or automatic reset and optional accessories like mechanical interlocks or extra auxiliaries.

Product comparison table

| Motor size (approx) | Example AF Contactor | Example Overload Relay | Typical use case |

|---|---|---|---|

| Up to ~4 kW | AF09-30-10-13 4 kW/9 A | EF19-1.0 electronic overload 0.3-1.0 A | Small pumps, fans in building services |

| Up to ~5.5 kW | AF12-30-10-11 5.5 kW/12 A | TF42 Thermal 2.3-3.1 A | Smaller production machines, HVAC drives |

| Around ~15 kW | AF30-30-00-13 15 kW/30 A | EF45-30 electronic overload 9-30 A | Medium-duty conveyors, mixers |

| Around ~22-30 kW | AF52-40-00-13 22 kW/52 A | EF45-45 electronic overload 15-45 A | Heavy duty fans, larger pumps |

| Around ~30 kW | AF65-30-00-11 30 kW/65 A | EF65-56 electronic overload 20-56 A | Packaging lines, industrial HVAC units |

| Around ~55 kW | AF116-30-11B-13 55 kW/116 A | TF96 Thermal 40-51 A | Large mixers, compressors, industrial applications |

| Around ~110 kW & above | AF205-30-11-13 110 kW/205 A | EF205-210 electronic overload 63-210 A | Heavy industrial motors, heavy plant |

Why choose ABB and LED for your complete panel solutions

When you choose ABB AF contactors and overload relays, you're choosing a unified system for modern control panels, allowing you to standardise from the smallest drive to the largest industrial machine.

By using ABB across your designs, you gain a consistent footprint, shared accessories, simplified wiring layouts and wide-range coils that remove the need to hold multiple voltage variants. So your panels are cleaner, engineering time is reduced and your inventory is under control.

At LED Controls, we stock and source every ABB contactor, overload relay, auxiliary block and matching accessory. So you can design, purchase and maintain your entire ABB-based control solution through a single, one-stop shop: LED Controls.

Get in touch to find out more:

01706 242050

[email protected]

ledcontrols.co.uk